Trusted Medical Injection Mold Manufacturer

Precision LSR & Plastic Molding Solutions for Healthcare & Diagnostics

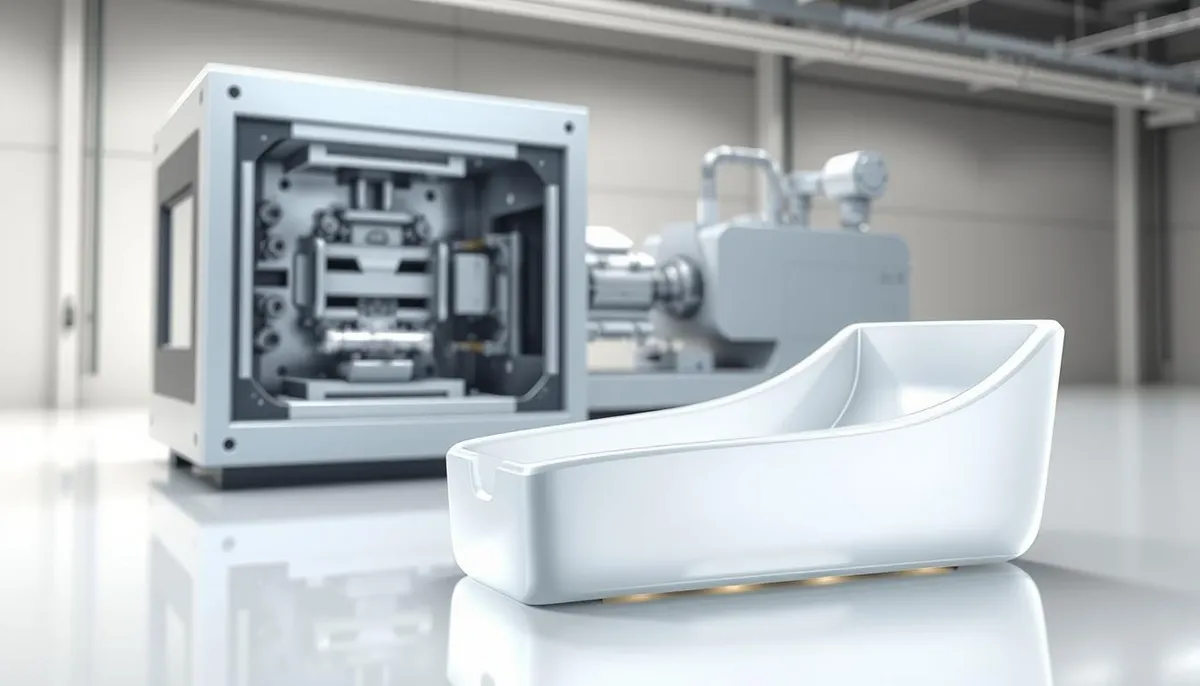

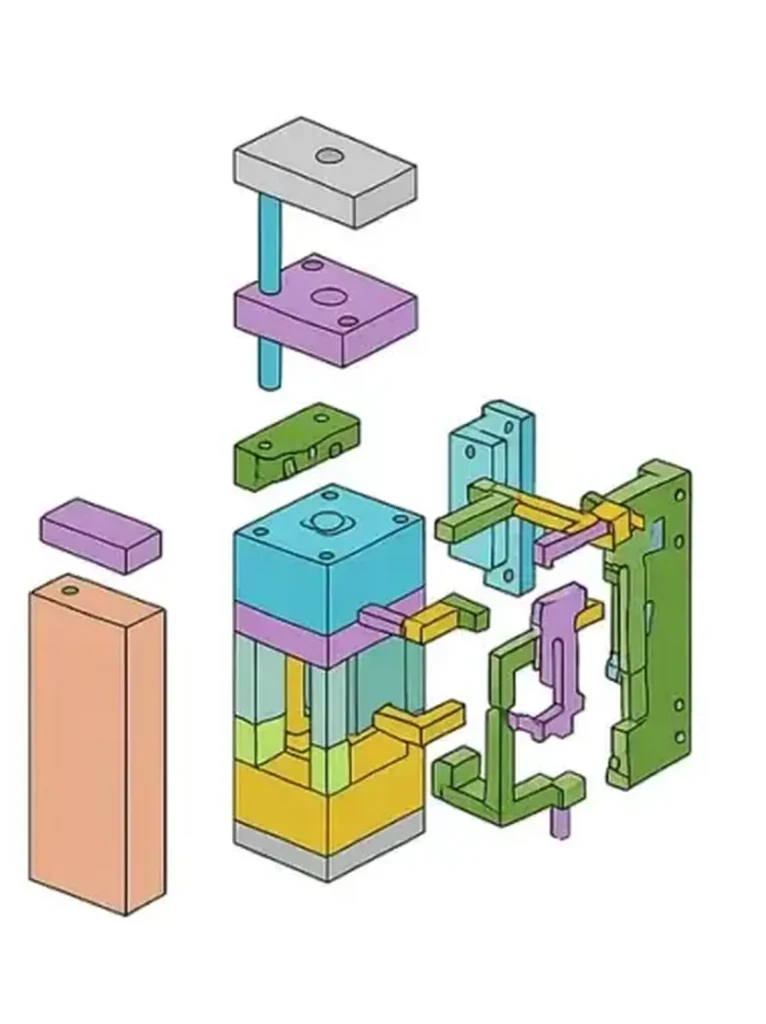

Product Display

Quality Only Happens When you Care Enough To Do Your Best.

We’re Your Partner From Prototyping to Production and Beyond

Unlimited Capacity

With our on-demand digital factories and extensive network of manufacturers, capacity concerns are a thing of the past. Enjoy consistent lead times, a variety of plastic and metal material choices, and a dependable supply chain. Quality parts delivered on time—always.

Design and Engineering Assistance

We provide both automated and live manufacturing support. Each quote includes a complimentary interactive manufacturability analysis to enhance part design efficiently. For any further inquiries, our application engineers are ready to discuss your project via WhatsApp at +86 135 5493 3315 or email us at [email protected]

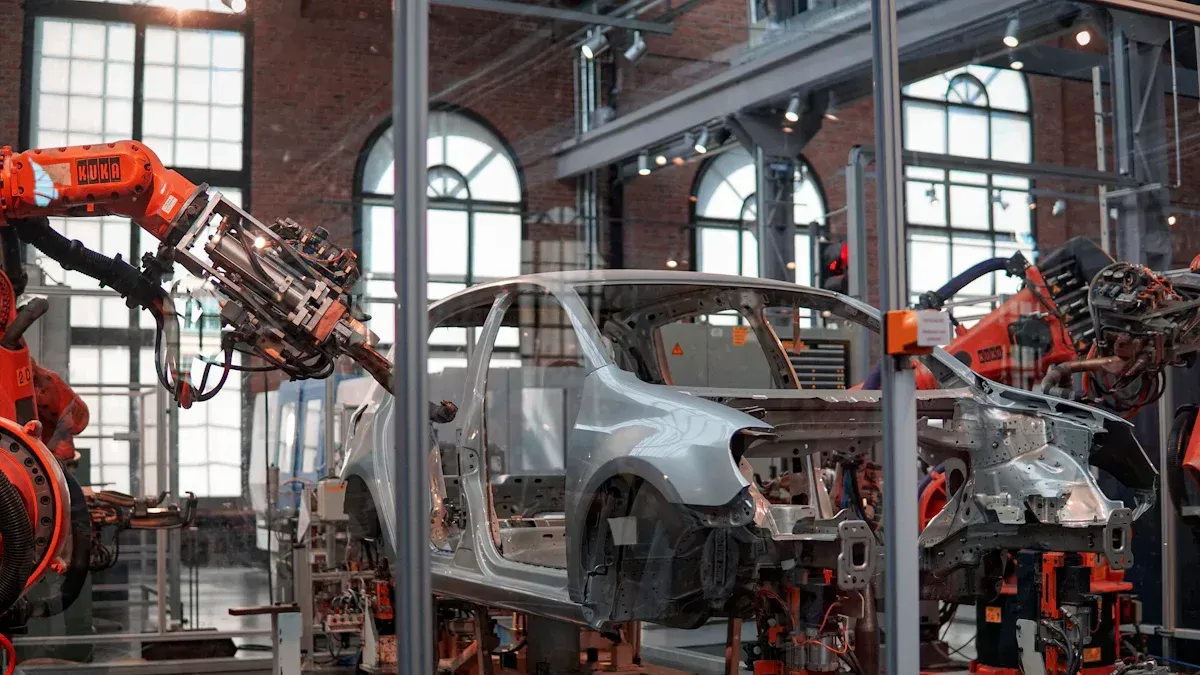

Work With Numerous Industries

From prototyping to production, GHXLD is dedicated to delivering superior quality and reliable functionality. Our extensive range of production-grade metal and plastic materials, combined with highly advanced on-demand manufacturing techniques, enable us to offer high-quality products across several industries.

Applications and Advantages

of Injection Molding

- Rapid Prototyping

Low-cost tooling allows for rapid injection molding to be produced in as fast as 10 business days at affordable prices.

- Production Parts

Injection Molding. Ideal for both low-volume production (250 units) and high-volume manufacturing (over 1,000,000 units), injection molding offers superior performance for plastic parts compared to CNC machining or 3D printing with the same material. By selecting the right resins, a wide range of properties and solvent compatibility can be achieved. Molds are CNC machined to high precision and tight tolerances, capable of producing thousands of identical parts with intricate details.

- Range of Industries and Certifications

We offer ISO 9001,AS9100,IS0 13485,UL, ITAR, and lSo 7 and 8 Medical Clean Room molding.

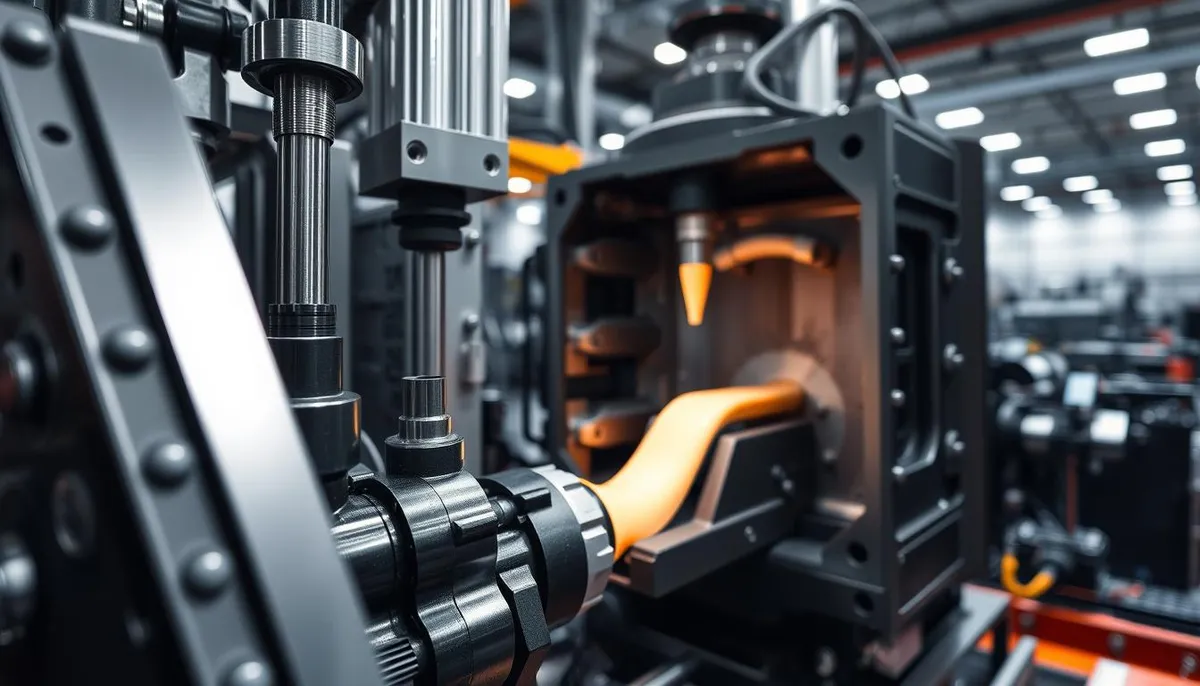

Our Injection Molding Service Processes

From quotation to final production, acknowledge the seamless order process at GHXLD. Our qualified team ensures you get your plastic molded parts within the provided lead times.

Request Instant Quote

DFM Report

Mold Design & MoldFlow

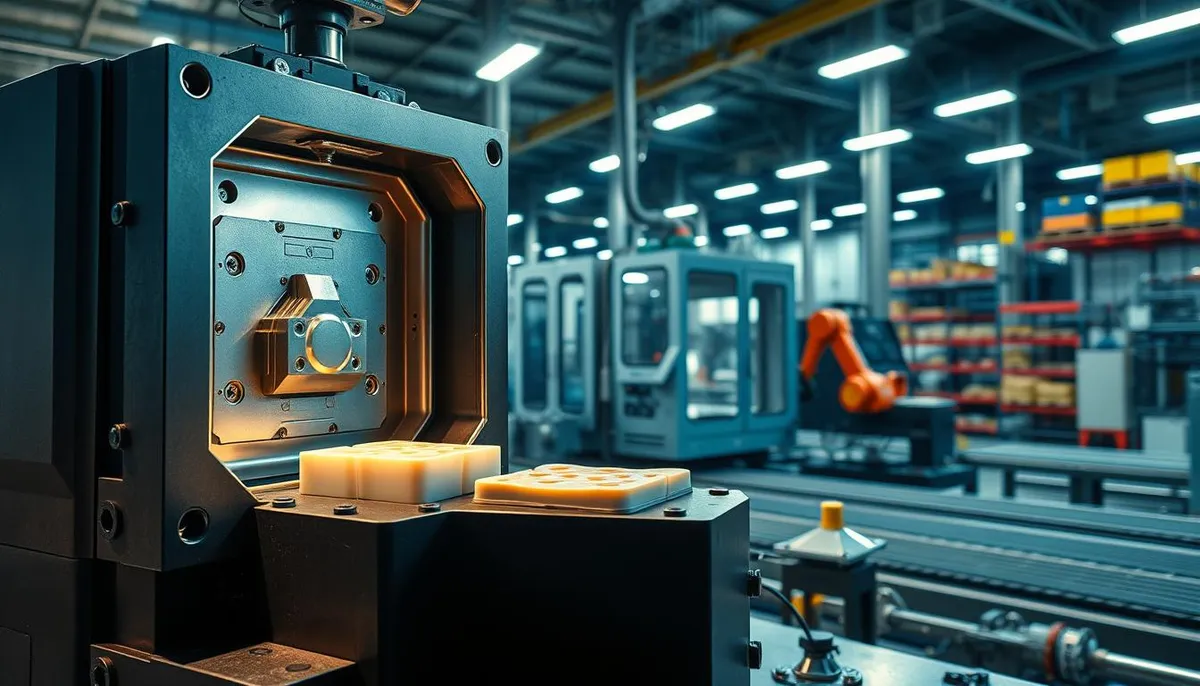

Mold Tooling Production

T1 Sample Inspection

Low Volume Production

Strict Inspection

Delivery

OUR PROJECTS

News & Media Center

Dedicated To Manufacturing Excellence