In the fast-paced world of high-volume manufacturing, injection molding has grown. It now focuses on being more efficient, αποδοτικός, and consistent. Multi-cavity injection molding is leading this change, changing how industries make large amounts of products.

With multicuspring — one mold has more products made in faster cycles. Saves money and ensures each product is great. It makes making things easier and lets small companies grow in large markets

We will explore the basics, benefits, and uses of multi-cavity injection molding. You’ll learn how to use it to improve your making skills and reach new levels.

Understanding Multi-Cavity Injection Molding Fundamentals

The art of mold design και cavity layout is key in injection molding. Knowing the basics of multi-cavity injection molding helps manufacturers improve efficiency and part quality. This section covers the essential concepts of this versatile technique.

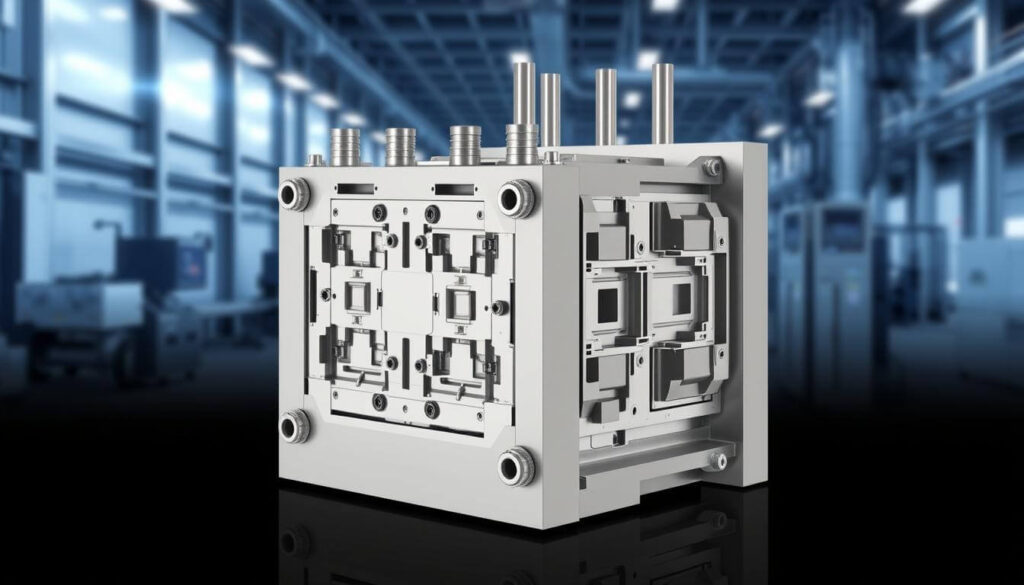

Basic Principles and Components

Multi-cavity injection molding makes many parts at once in one mold. The design of the mold ensures even flow and quality in all parts. Important parts include the mold base, runners, gates, and ejector system. They work together to make precise products.

Advantages in Having Multiple Cavity Molds

- Increased throughput: Fewer cycle times are achieved with part-on-part instead of one part at a time.

- Decreased Cost-efficiency: The mold cost is only charged per part in a diminished fashion.

- Better part repeatability: Good solid modeling and tight controls mean parts are uniform, exactly what the engineering gods demand.

Versatility in the manufacturing — multi-cavity molds works for many industries and applications.

Common Applications in Manufacturing

Multi-cavity injection molding is used in many fields. It’s popular in consumer goods, automotive, electronics, ιατρικές συσκευές, and packaging. This method helps make production faster, waste less, and improve mold design, cavity layout, και part quality.

| Βιομηχανία | Common Multi-Cavity Molded Products |

|---|---|

| Consumer Goods | Household items, toys, and personal care products |

| Automotive | Interior trim, exterior components, and underhood parts |

| Electronics | Connectors, housings, and small electronic components |

| Ιατρικός | Syringes, medication containers, and surgical instruments |

| Συσκευασία | Lids, caps, and other rigid plastic packaging |

“The key to unlocking the full potential of multi-cavity injection molding lies in understanding the fundamental principles and using them to drive innovation in manufacturing.”

Essential Design Considerations for Multi-Cavity Molds

Creating effective multi-cavity molds needs a deep understanding of key factors. These include the best cavity layout, cooling system, and ejection mechanisms. Each part is vital for consistent part quality and better production efficiency.

Cavity Layout: Balancing the Mold

The way cavities are arranged in the mold is crucial. A good layout ensures even material flow, θερμοκρασία, and part size across all cavities. By placing cavities wisely, based on part shape and material, you can achieve this balance and reduce part differences.

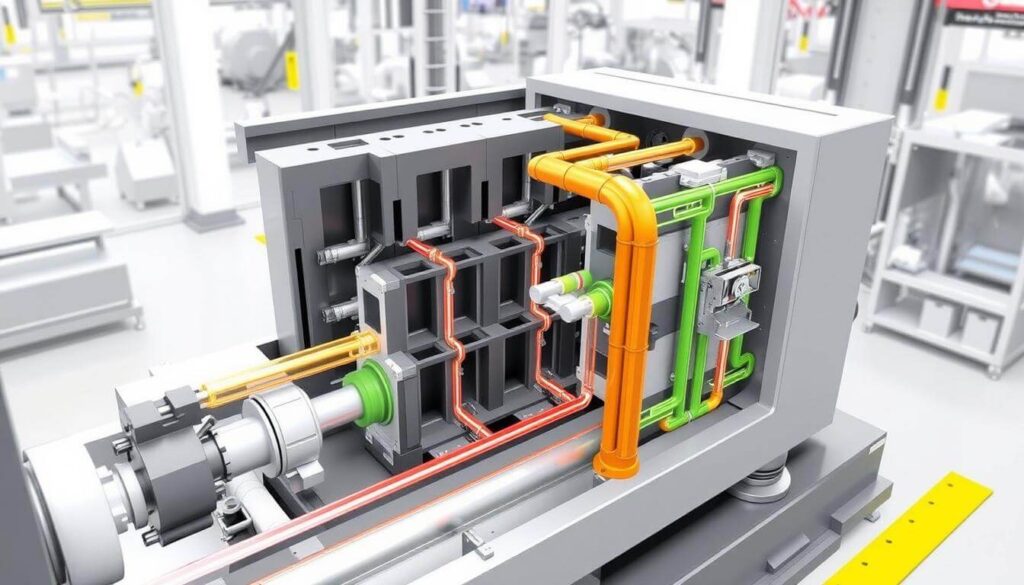

Cooling System: Keeping Things Chilled

Ο cooling system is key for multi-cavity molds. Good cooling channels and the right cooling element placement keep mold temperatures steady. This reduces warping and improves part quality. A well-designed cooling system also speeds up production, making it more efficient.

Ejection System: Smooth Part Removal

Ο ejection system is vital for removing parts from the mold reliably and consistently. A well-designed ejection system, tailored to the part and mold, ensures parts come out smoothly without damage. This boosts production consistency and efficiency.

By focusing on these design elements, manufacturers can fully benefit from multi-cavity injection molding. They can produce high-quality parts faster and at a lower cost.

| Design Consideration | Importance | Key Factors |

|---|---|---|

| Cavity Layout | Ensures consistent part quality and minimizes variability |

|

| Cooling System | Maintains consistent temperatures and improves cycle times |

|

| Ejection System | Ensures reliable and consistent part removal |

|

“Achieving a well-balanced mold design is essential for unlocking the true potential of multi-cavity injection molding.”

Optimizing Runner Systems and Gate Locations

Designing an efficient runner system and strategically placing gates are key to better multi-cavity injection molding. Balanced runner design ensures even melt flow and consistent part quality. This is crucial for all cavities.

Balanced Runner Design Strategies

To get a balanced runner system, experts suggest these strategies:

- Use a balanced branching pattern to spread the melt flow evenly among all cavities.

- Adjust the runner’s cross-sectional area and length to reduce pressure drops and ensure consistent injection pressure.

- Use flow simulation analysis to spot and fix any runner system imbalances.

Gate Placement and Sizing

The right gate placement and sizing are vital in multi-cavity molding. They help improve part quality and efficiency:

- Place gates to ensure even melt flow into each cavity.

- Choose the right gate size to keep injection pressure optimal and fill times consistent.

- Use flow simulation tools to analyze and improve the gating system.

Flow Pattern Analysis

Understanding flow patterns in multi-cavity molds is key to solving issues and improving the molding process. Advanced simulation software and thorough testing help manufacturers:

- Spot imbalances in melt flow and pressure.

- Find ways to improve part quality and consistency.

- Enhance the runner system και gate design for better efficiency.

By focusing on balanced runner design, strategic gate placement, and detailed flow pattern analysis, manufacturers can maximize multi-cavity injection molding. This leads to better productivity, part quality, and competitiveness.

Material Selection and Processing Parameters

Getting consistent quality in multi-cavity injection molding needs careful thought on material and process settings. The right polymer material is key. It must fit the product’s needs and ensure even flow and cooling in all mold cavities.

Adjusting the melt temperature και injection pressure is vital. This balance helps in even filling and reduces part defects. It ensures the product quality stays high and consistent.

You will also need the right cooling time. Parts should solidify correctly and dimensions should not change when cooling out proper. Which, in turn still boosts general quality and smoothness on the part of the manufacturing process. Optimising these parameters would enable manufacturers to increase productivity and offer world-class products.

Master multi-cavity injection molding is a good method to improve the productivity, decrease your cost and best result in your molded part quality consistency. Understanding both the advantages and disadvantages, together with best design practices for material flow and cooling as well as manufacturing maintenance manufacturers can unlock multi-cavity molds full potential in high volume production.

FAQ

The main advantages are making more parts faster, saving money, and getting consistent quality. By making lots of parts together, you can work more efficiently. This also lowers the cost per part and keeps all parts the same.

Important design points include the best layout for cavities, a good cooling system, and how parts are ejected. A well-designed mold is key for making parts the same and working efficiently.

To improve runners and gates, balance their design, place them wisely, and analyze flow patterns. These steps help make parts better, reduce cycle times, and increase efficiency.

Choosing the right material and adjusting melt temperature, injection pressure, και cooling time are crucial. These settings affect how consistent parts are and how well the process works for all cavities.

推动创新和卓越。