Medical Injection Molding

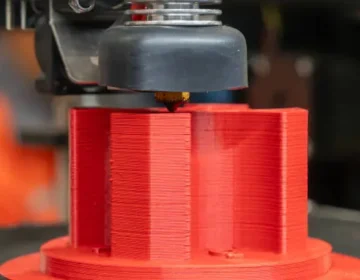

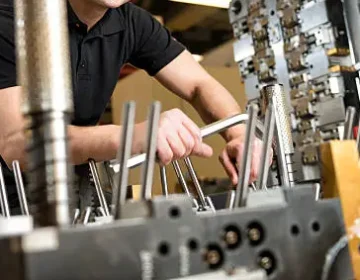

GHXLD partners with leading medical device manufacturers, wearable technology startups, suppliers, and research institutions to expedite rapid prototyping and efficiently scale production capabilities. 500 medical product and equipment companies trust our advanced manufacturing solutions, cutting-edge medical injection molding. These services support a wide range of needs, such as rapid prototyping, product testing, custom tooling, and bespoke manufacturing designs.

Scope of business

Medical products

- Medical consumables molds and products

- Respiratory nursing

- Guardianship

- Intervention class

- Molds and products for food and daily chemical packaging

In vitro diagnostics

- Plastic consumables for IVD and POCT industries

- Plastic consumables for cuvette and reaction disk

Custom Prototypes and Parts

Medical Consumables

Connector

Medical Consumables

Medical Consumables

Breathing Mask

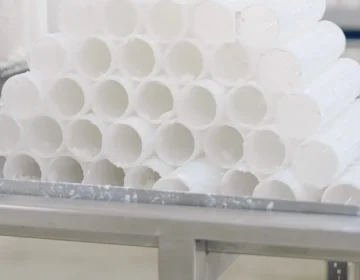

Test Tube

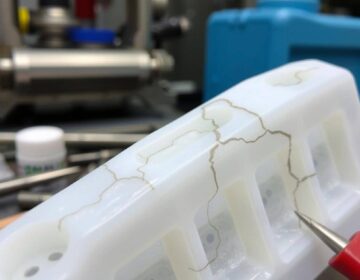

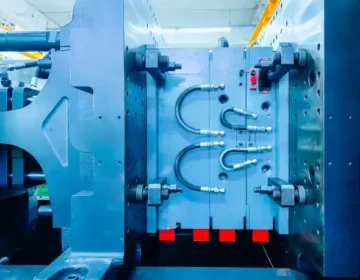

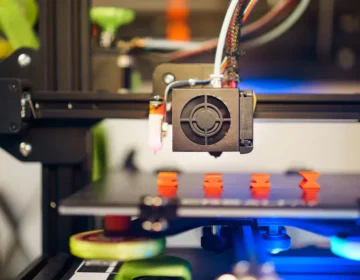

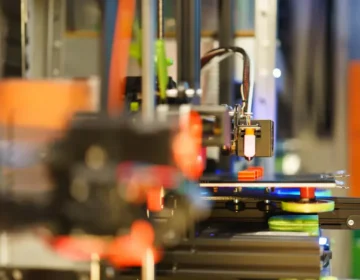

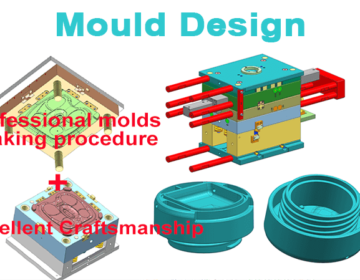

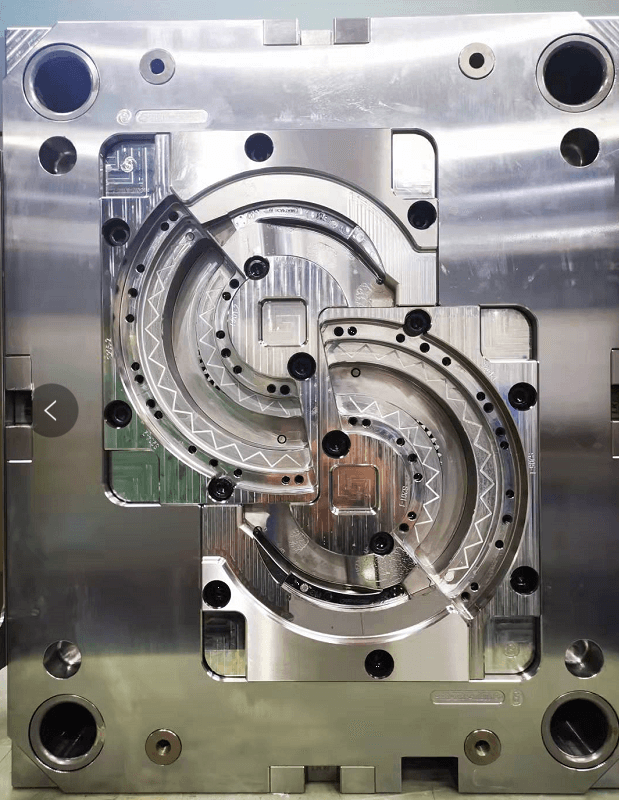

Die application——Plastic mould

Provide infusion set, laryngoscope, puncture support, respiratory mask, pipette dripper, blood collection vessel and other medical consumables product molds

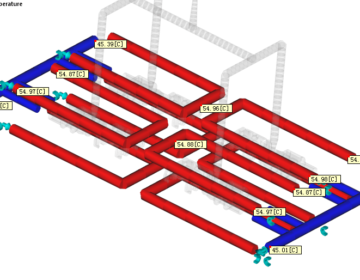

- Find out the best position of glue inlet gate through mold flow analysis to ensure uniform wall thickness of products

- Ensure the appearance defects of gate position through spiral nozzle core and reasonable cooling

- Motion simulation analysis is adopted to ensure the best arc core pulling

- Adopt advanced coating technology to ensure that the inner wall of the product is free of flowers

- Adopt advanced technology to prevent lens surface from atomization

What Materials Work Best for Medical Applications?

PEEK has strong chemical resistance, radiation resistance, and wear resistance. Due to its incredible heat resistance, PEEK is suitable for sterilization and injection molding. It is commonly used in orthopedic instruments, dental implants, healing caps, and spinal fusion devices.

This thermoplastic material with high molecular weight is suitable for wearable medical devices. However, PE cannot be sterilized using high-pressure sterilizers due to its poor heat resistance.

PP has high heat resistance, making it ideal for producing parts that require regular sterilization with high-pressure sterilizers. PP is also tough, lightweight, αποδοτικός, and resistant to radiation, chemicals, electricity, and organic solvents.

PS offers good impact resistance and dimensional stability. It is non-toxic, affordable, tasteless, FDA-συμβατό, and lightweight, making it suitable for petri dishes and test tubes.

This robust and flexible engineering thermoplastic has high vibration resistance, heat resistance, impact resistance, and UV resistance. PC has good dimensional stability and is commonly used in medical instruments.

Choosing materials for medical injection molding involves considering not only use cases and specific material properties but also:

Durability and Strength

In the medical field, using fragile materials is not feasible. It's essential to choose materials that are resistant to breakage and fracture, ensuring the necessary durability and strength for the specific medical applications.

Operating Conditions

Before selecting a material, it's important to evaluate the operating environment. For instance, if parts will undergo frequent sterilization or be exposed to high temperatures, heat-resistant materials like polypropylene should be used. For parts that require both flexibility and durability, materials such as polycarbonate are ideal.

Ease of Use

Consider the end user and the intended use of the part. Ergonomically inefficient and cumbersome surgical instruments can hinder performance. Lightweight, ergonomic, and easy-to-sterilize instruments not only enhance functionality but also improve efficiency in the medical setting.

We're Supplier,

Ready To Start Your Next Project?

Feel free to contact us and send your need

Related Resources