Precision engineering is key in today’s manufacturing. Injection molding leads this technology. It boosts accuracy and efficiency in making products. This method is great for creating complex parts with exact sizes.

Manufacturing benefits a lot from precision injection molding. It makes high-quality products with little waste. It’s perfect for detailed designs or small parts. This is why it’s used in the automotive and medical fields, where precision is vital.

Exploring precision injection molding reveals its many benefits. We’ll look at its basics, advantages, and uses. We’ll also see how it fits into modern manufacturing and precision engineering.

Introduction to Precision Injection Molding

Precision injection molding uses molds to make precise parts. It’s used across many industries for its quality and efficiency. It helps cut costs and improve product quality, making it a good choice for businesses.

Key Takeaways

- Precision injection molding offers increased accuracy and efficiency in production processes

- This method allows for the creation of complex parts with precise dimensions

- Precision injection molding is ideal for industries that require intricate designs or small parts

- The use of precision injection molding can help companies reduce production costs

- Precision engineering is crucial in modern manufacturing, and injection molding is a key aspect of this technology

- Precision injection molding has various applications in industries such as automotive and medical device manufacturing

Understanding Precision Injection Molding Fundamentals

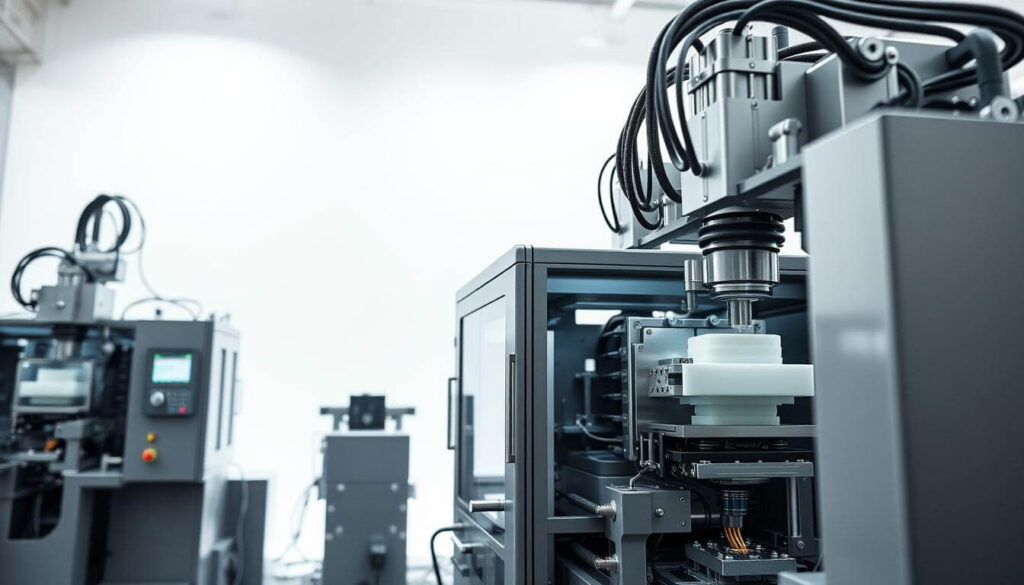

Precision injection molding is a complex process. It needs a deep understanding of its core components and technical specs. At its heart, it uses injection molding machines to make precise and detailed parts. These machines work with plastic molding materials, which are melted and injected into a mold to form the desired shape.

The quality of the injection molding machines greatly affects the process. These machines must keep precise temperatures and pressures. This ensures parts are made accurately and consistently. The type of plastic molding material used is also key. It must handle the high temperatures and pressures of the molding process.

- Machine capacity and capability

- Material selection and compatibility

- Mold design and construction

- Process control and monitoring

Understanding these basics of precision injection molding helps manufacturers improve their processes. They can make high-quality parts with precision and consistency. Choosing the right injection molding machines και plastic molding materials is crucial for achieving the best results.

Advantages of Modern Precision Injection Molding Technology

Precision injection molding is key in many manufacturing processes. It brings many benefits that boost productivity and efficiency. It allows for making high-quality items with complex shapes and tight fits. This makes it perfect for industries needing precision and accuracy.

Key benefits include less material waste, better efficiency, and higher product quality. These are big pluses in fields like the automotive, ιατρικός, and electronics sectors. Για παράδειγμα, it helps make detailed parts with complex designs. This cuts down on extra work and waste.

It also has economic perks. Companies save on costs by using less material and working more efficiently. Plus, it ensures products are made with high precision and quality. This means less need for fixing mistakes and better products overall. Precision injection molding is a valuable tool for improving manufacturing processes.

Many industries have seen success with precision injection molding in their manufacturing processes. These include:

- Automotive industry: it’s used for parts like engine components and dashboard trim.

- Medical devices: for making precise medical tools and implants.

- Consumer electronics: for parts like smartphone cases and laptop components.

By using precision injection molding, companies can make their manufacturing processes better. They can cut costs and improve product quality. This gives them a competitive edge in their markets.

Comparing Manufacturing Processes: Where Precision Injection Molding Excels

Precision injection molding is a top choice for making high-quality products. It’s known for its exact engineering. This method is unmatched in quality control, especially in industries needing precision and reliability.

Compared to other methods, precision injection molding has big advantages. It can make complex shapes with great accuracy. It’s perfect for projects needing precision engineering. Plus, it works with many materials like plastics, metals, and ceramics.

- High-volume production capabilities

- Consistent product quality

- Ability to produce complex geometries

- Wide range of material options

Precision injection molding is both versatile and reliable. It shines in quality control και precision engineering. Its skill in creating high-quality, complex products makes it a top pick for many industries.

Cost Analysis and ROI Considerations

When looking into precision injection molding, it’s key to check the costs and potential return on investment (ROI). The price of injection molding machines is high, but it can be balanced by the gains in efficiency and productivity. Companies that have adopted precision injection molding have seen a big ROI. This is thanks to lower labor costs and better product quality.

Important things to think about when looking at the cost of injection molding machines include:

- Initial equipment costs

- Operating and maintenance costs

- Material costs

- Labor costs

By carefully looking at these points and thinking about the benefits of precision injection molding, companies can make a smart choice. With the right tools and knowledge, precision injection molding can be a very effective and profitable way to make products.

Quality Control and Consistency in Precision Injection Molding

Precision injection molding needs top-notch quality control and consistency. This is key in plastic molding, where tiny changes can make a big difference. To keep things consistent, makers use advanced quality checks like statistical process control and total quality management.

These methods watch over every part of the manufacturing processes, from start to finish. This way, any problems or variations are caught and fixed early. This leads to better quality products. Also, meeting industry standards is vital. It makes sure products are safe and work well in different uses.

- Regular equipment upkeep

- Training staff well

- Choosing top-notch raw materials

- Quality checks at every step

By using these methods, makers can make sure their products are up to standard. This means happy customers and more loyalty.

Industries and Applications Best Suited for Precision Molding

Precision injection molding is a flexible process used in many fields. It’s great for making high-quality items with complex shapes and exact sizes. This ensures quality control and precision engineering.

Some of the industries that benefit from precision injection molding include:

- Automotive: precision molding is used to create components such as dashboard trim, door handles, and engine parts, requiring high precision engineering και quality control.

- Medical devices: precision molding is used to create medical devices such as surgical instruments, implantable devices, and diagnostic equipment, where quality control is crucial.

- Consumer electronics: precision molding is used to create components such as smartphone cases, laptop keyboards, and gaming console parts, requiring high precision engineering and attention to detail.

Companies like Apple, General Motors, and Medtronic have used precision injection molding. They show how well this method works for making top-quality items with complex shapes and tight tolerances.

In conclusion, precision injection molding is a versatile method. It’s used in many fields, including the automotive, ιατρικός, and electronics sectors. It ensures high quality control και precision engineering.

Environmental Impact and Sustainability Factors

The world is moving towards more sustainable practices. This includes looking at the environmental impact of how things are made. Injection molding και plastic molding are big concerns because they use a lot of energy, create waste, and release emissions.

To make things better, manufacturers can do a few things. They can:

- Use energy-saving equipment and methods

- Choose recycled materials and cut down on waste

- Make production runs more efficient to lower emissions

Also, companies are making sustainable products with injection molding και plastic molding. They use materials that can be recycled, make products last longer, and cut down on packaging waste.

By using sustainable methods and reducing waste, manufacturers can lessen the harm to the environment. This helps the planet and makes companies look good for caring about the environment.

Σύναψη: Making the Right Choice for Your Manufacturing Needs

Ακρίβεια engineering και quality control are key to success in precision injection molding. This method is very accurate and efficient. It’s used in many fields like cars, medicine, and electronics.

Using precision injection molding can help your business grow. It saves money and supports sustainable production. It’s a great way to innovate and improve your products.

If you want to make your manufacturing better or create new products, think about precision injection molding. Working with a trusted provider ensures your project is top-notch. This technology can make your products better and keep you competitive.

The injection molding process is complex and creates plastic products. Dark spots are a common issue that affects these products