GHXLD Manufacturing Capabilities

GHXLD: Efficient Production and Fast Delivery with Advanced Equipment

En GHXLD, we leverage advanced injection molding, mold manufacturing, and processing equipment to ensure high-quality production and operational efficiency. Our use of cutting-edge technology optimizes the entire production process, enabling quick responses to customer needs and on-time delivery.

Key Advantages for Fast and Efficient Production:

- Agile Production Process: We adopt flexible production methods that allow rapid adjustments to meet customer demands. Streamlined workflows and reduced wait times enhance overall efficiency.

- Strong Supply Chain Management: GHXLD has established long-term relationships with reliable suppliers to guarantee timely delivery of materials, minimizing delays and ensuring smooth production flow.

- Advanced Technology and Equipment: Our state-of-the-art, automated production equipment boosts both speed and quality. This high-tech machinery ensures fast, precise manufacturing, meeting diverse production needs.

- Flexible Human Resources: GHXLD’s skilled team is adaptable, quickly reallocating resources to meet urgent demands while maintaining production schedules.

- Optimized Logistics: We partner with trusted logistics providers to ensure products reach customers on time. Our proactive approach allows us to quickly address any logistics issues that may arise.

- Emergency Delivery Plans: GHXLD has a tailored emergency delivery strategy, prioritizing urgent orders and adjusting resources to guarantee rapid turnaround when needed.

- Continuous Improvement: We continuously analyze our processes to identify bottlenecks and optimize efficiency. Customer feedback is integral to our ongoing improvements, ensuring better service and faster delivery.

With these strengths, GHXLD consistently delivers high-quality products and exceptional service, meeting the unique demands of our customers and ensuring timely delivery.

- Efficient Production: Fast injection speeds and cycle times enable quick, efficient molding, reducing lead times and improving delivery speed.

- Precision and Consistency: High-precision control systems ensure consistent product quality, reducing defects and ensuring size accuracy.

- Automation: Automated processes such as feeding, molding, and demolding minimize manual intervention, boosting production efficiency and consistency.

- Quick Mold Change: Advanced mold equipment allows for fast mold changes, reducing downtime and enabling flexible production to meet customer needs.

- Cost Savings: Automation reduces labor and energy costs, while precision control minimizes scrap rates and improves product consistency, reducing overall production costs.

- Data Tracking and Analysis: Real-time data collection and analysis allow us to identify and address production issues quickly, enhancing efficiency and product quality.

By integrating advanced mold equipment and automated injection molding, we enhance production speed, accuracy, and cost-effectiveness, ensuring fast delivery of high-quality molded parts.

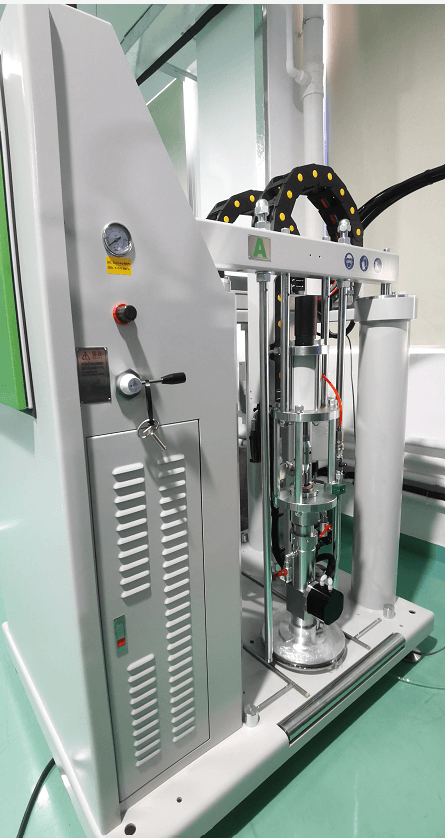

Injection molding Capabilities

máquina de moldeo por inyección

At present, it has more than 10 100-180 ton injection molding machines imported from Japan, including 2K, vertical injection molding machines and 2K liquid silica gel machines.

Configure independent peripheral auxiliary equipment imported from Japan.

Post process and assembly capacity

Pad printing / laser marking, ultrasonic welding / hot melting, etc.;

Workshop environment

The workshop decorated according to 10W level shall be purchased with strict production management,

Basically meet the initial bacterial test standards of class I / II products of customers;

Injection molding Engineering Management

Through advanced analysis software and scientific injection management, it can ensure the optimization of injection molding factors and parameters of each product

Ensure production stability

WHY CHOOSE US?

GHXLD Quality capacity

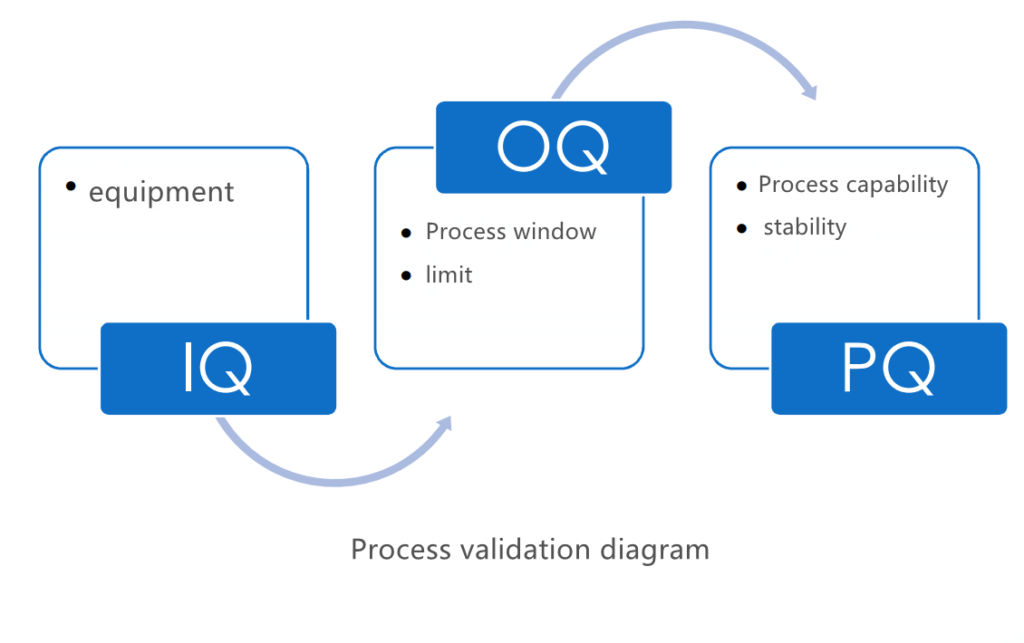

IQ/OQ/PQ Verification and Control:

- Full set of Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) processes to ensure proper equipment setup, operational functionality, and performance under production conditions.

GR&R / FAI / CPK Analysis

- GR&R (Gage Repeatability and Reproducibility): Ability to perform GR&R studies to assess measurement system variability and ensure measurement accuracy.

- FAI (First Article Inspection): Capability to conduct detailed inspections of the first article to confirm that it meets design specifications and quality standards before full-scale production begins.

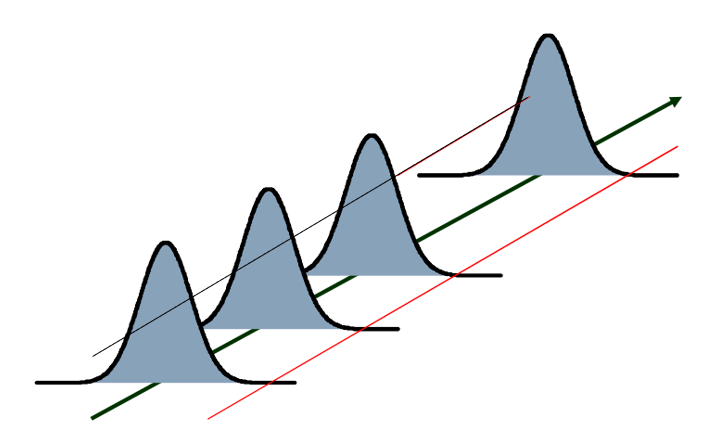

- CPK (Process Capability Index): Proficiency in performing statistical analysis to evaluate the ability of the manufacturing process to meet design specifications consistently, ensuring long-term process stability and product quality.

Key Product Characteristics Identification and Control

Expertise in identifying critical-to-quality (CTQ) parameters and implementing effective control measures to ensure these key characteristics are consistently met throughout the manufacturing process.8D Problem-Solving Analysis

Ability to apply the 8D (Eight Disciplines) methodology for root cause analysis and systematic problem-solving, enabling the identification, correction, and prevention of recurring quality issues in production.

Robust Quality Processes

By leveraging advanced software systems, GHXLD provides expert analysis across three key areas:

- Modeling & CAD: Using industry-leading software like Unigraphics NX, Pro E, and Catia, we collaborate seamlessly with your design teams worldwide to create reliable, precision-engineered products.

- Ansys Finite Element Analysis (FEA): This tool validates the functionality of designs, ensuring that both new and modified products meet performance requirements and are fit for purpose.

- Autodesk Moldflow Insight (AMI): Our use of AMI simulation software optimizes part and mold designs, minimizing risks and ensuring the consistent delivery of high-quality final products.

En Ghxld, these advanced technologies enable us to refine designs, improve product performance, and reduce production risks, all while maintaining exceptional quality standards.

Key Quality Assurance Strategies:

Stage Gate Process for New Product Introductions: For new product launches and production transfers, we follow a meticulous stage gate process. This includes Process Failure Mode Effects Analysis (PFMEA) and the development of comprehensive control plans to identify and mitigate potential process risks at every stage, ensuring superior product quality.

Continuous Improvement: Through our commitment to continuous improvement, we minimize defects, optimize efficiency, and consistently exceed customer expectations. GHXLD’s focus on robust quality systems guarantees flawless products, every time.

Advanced Monitoring Techniques:

Digital In-Process Control: We utilize cutting-edge techniques for real-time process monitoring, including poka-yoke devices y manual inspections, to uphold the highest quality standards.

3D Laser CMM: For non-contact inspection, we use 3D laser CMM technology to validate finished products, ensuring precision and accuracy when necessary.

With GHXLD, you can trust that our unwavering commitment to quality, advanced monitoring systems, and continuous development will result in efficient, high-quality molding and assembly services, every time.

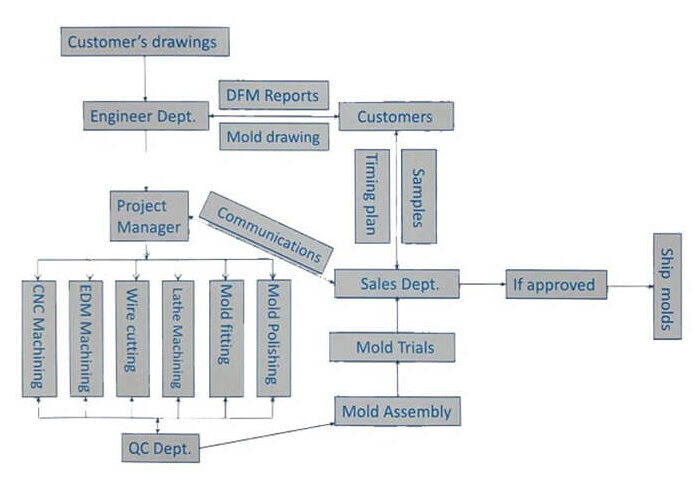

Project Flow Chart

Ready To Start Your Next Project?

Get a quote now!

BRING YOUR PROJECT TO LIFE AT ADVANCED PROTOTYPE MOLDING