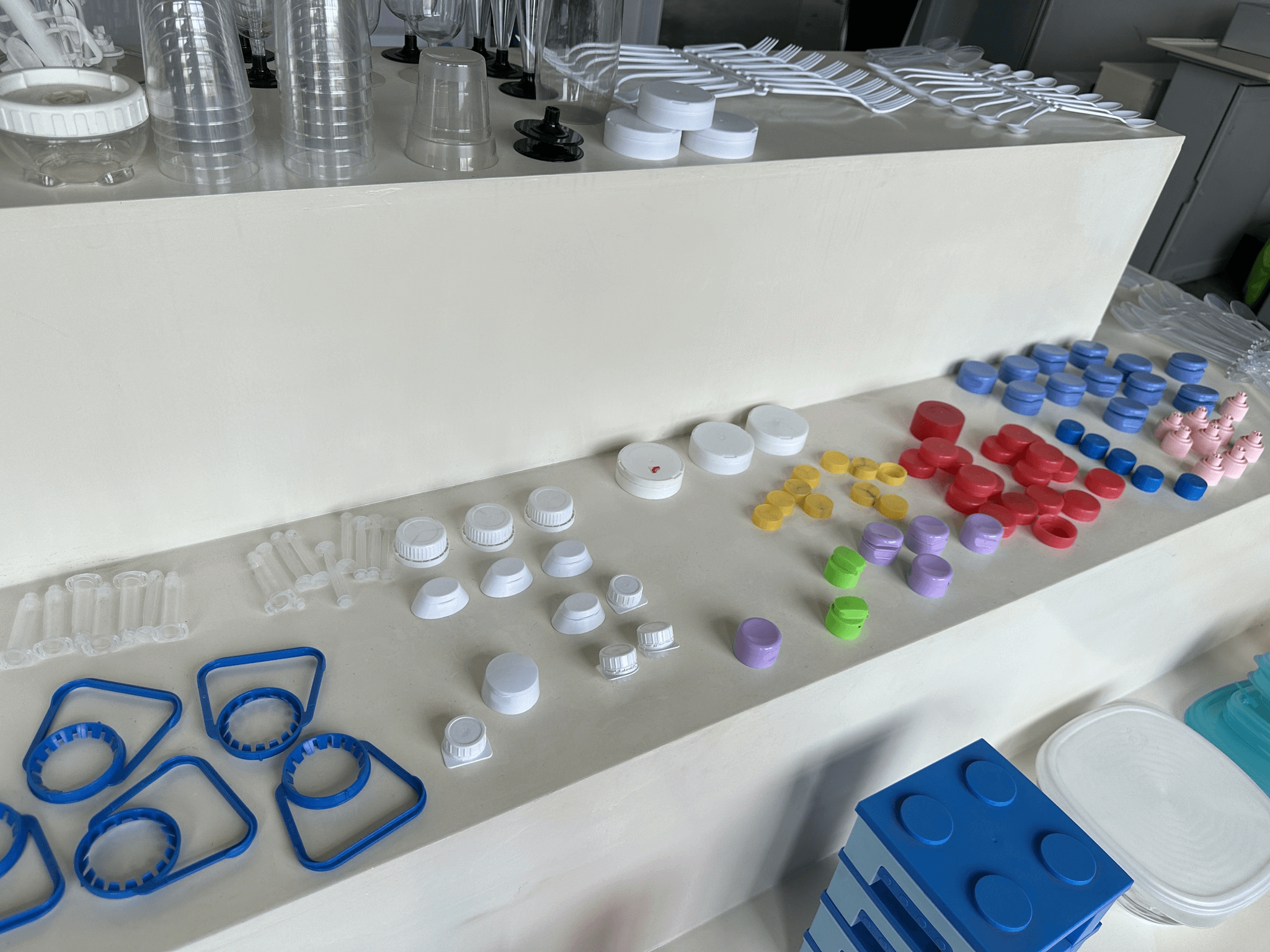

Flip Top Mold Flow Analysis and Design

Mold Flow Analysis:

Mold flow analysis is essential before designing a bottle cap flip-top mold. It helps evaluate the mold design, predicts material, heat, and air flow during injection, and identifies potential defects. This analysis optimizes mold structure, improves filling performance, and enhances product quality, reducing production issues.

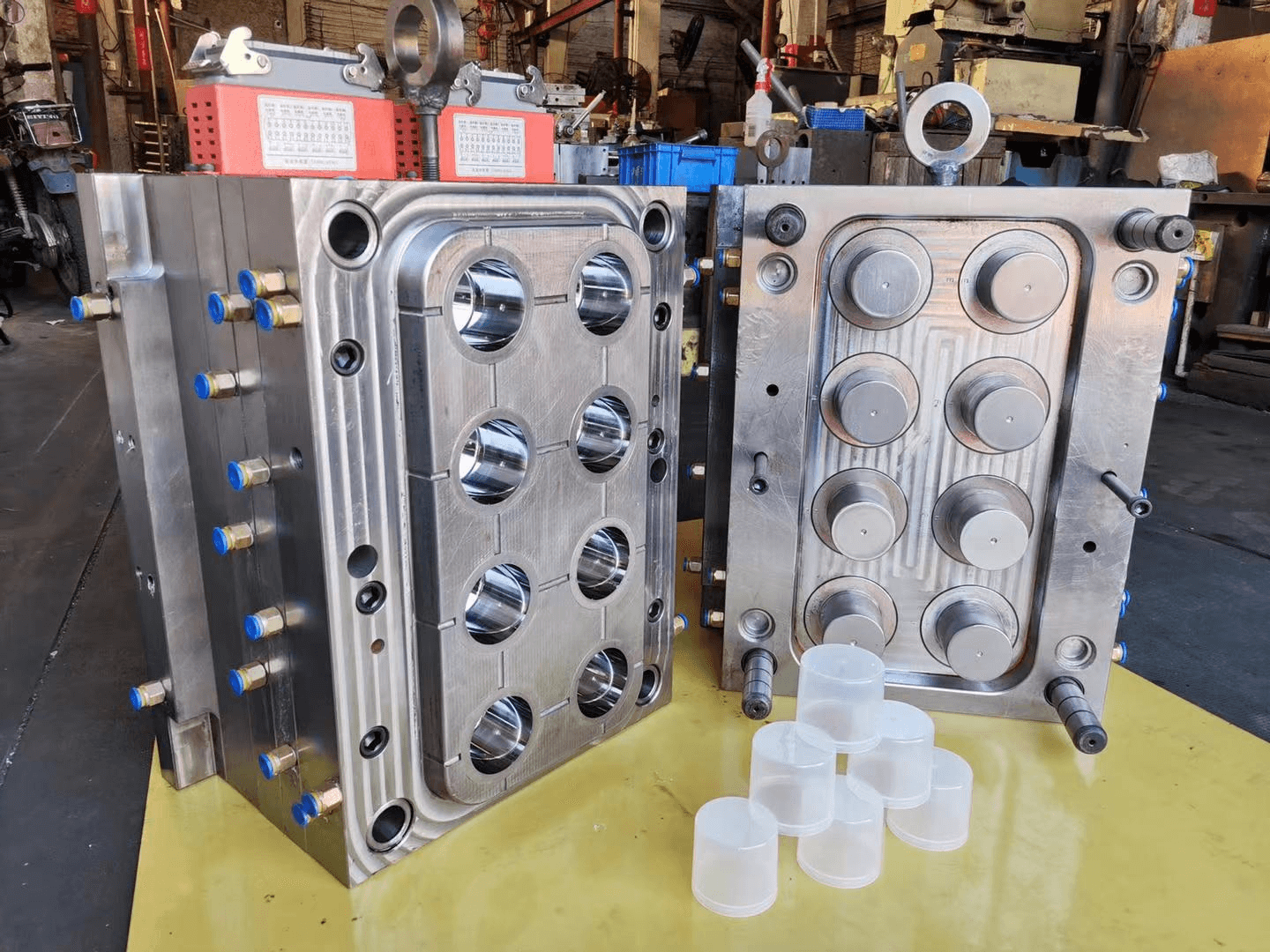

Mold Design:

Designing a bottle cap mold involves several key factors:

- Mold Structure: The mold must be designed to accommodate the cap’s shape and size, considering filling performance, cooling, and ejection efficiency.

- Material Selection: High-quality materials like alloy steel or stainless steel ensure durability, wear resistance, and corrosion resistance.

- Cooling System: A well-designed cooling system accelerates cooling speed, reducing the production cycle time.

- Processing Technology: Advanced techniques like CNC machining, EDM, and wire cutting ensure precision and mold quality.

In summary, effective mold flow analysis and design are crucial to optimizing bottle cap production, improving efficiency, and ensuring high-quality outputs that meet market demands.

Optimized Microcellular and Multi-Cavity Extrusion for Medical Tubing Manufacturing

Microcellular and multi-cavity extrusion technologies are increasingly essential in the production of specialized medical tubing, including catheters, infusion tubes, and hemodialysis tubes. These processes are particularly suited for producing tubes that require specific attributes such as flexibility, durability, and biocompatibility.

Microcellular Extrusion

Microcellular extrusion involves creating tiny pores or holes on the surface of the tubing. This microporous structure can deliver essential functionalities like gas permeability and liquid filtration, which are crucial for applications in respiratory equipment, filtration systems, and other medical devices.

Multi-Cavity Extrusion

Multi-cavity extrusion allows the production of tubing with multiple layers, each serving a unique purpose. This technology enables the creation of multi-functional tubes, such as those designed for drug delivery, where one chamber delivers medication, and another transports a carrier liquid.

Benefits and Applications

Both microporous and multi-cavity extrusion offer significant advantages in medical tubing manufacturing, including high precision, efficiency, and consistent quality. These methods are especially valuable in meeting the strict performance standards of the medical industry, enabling large-scale production without compromising on quality.

Precision and Versatility

At GHXLD, we offer advanced extrusion capabilities for manufacturing medical tubing with high-performance materials. Our expertise allows us to produce thin-walled tubes, tight tolerances, and complex geometries, making us an ideal partner for both rapid prototypes and large-scale production runs. Whether you require custom medical tubing or high-volume manufacturing, our solutions are tailored to meet your specific needs.

Reviews

There are no reviews yet.