Dans ce monde en constante évolution d'aujourd'hui, Les entreprises essaient constamment de trouver la meilleure façon de tout faire. Ils cherchent à trouver des techniques à la fois intemporelles et bon marché. Il vient dans ces deux énormes champs comme la fabrication additive, ou l'impression 3D et la moulure traditionnelle en plastique. Il y a un avantage et des inconvénients pour chacun, il est donc important de s'assurer que l'on a choisi le droit pour chaque projet.

Un examen plus approfondi de l'impression 3D contre le moulage par injection indique qu'il n'y a pas de meilleur choix dans cette industrie. Il existe de nombreux facteurs qui décident du bon choix allant du coût du premier article,point pivot pour combien vous prévoyez de faire, complexité du design, matériel, Et ce qui affecte jamais l'environnement. C'est ainsi que les entreprises peuvent décider quelle méthode utiliser dans l'ordre et cela correspond à leurs besoins et leurs objectifs.

Comprendre les fondamentaux: Moulage par injection, 3D Impression

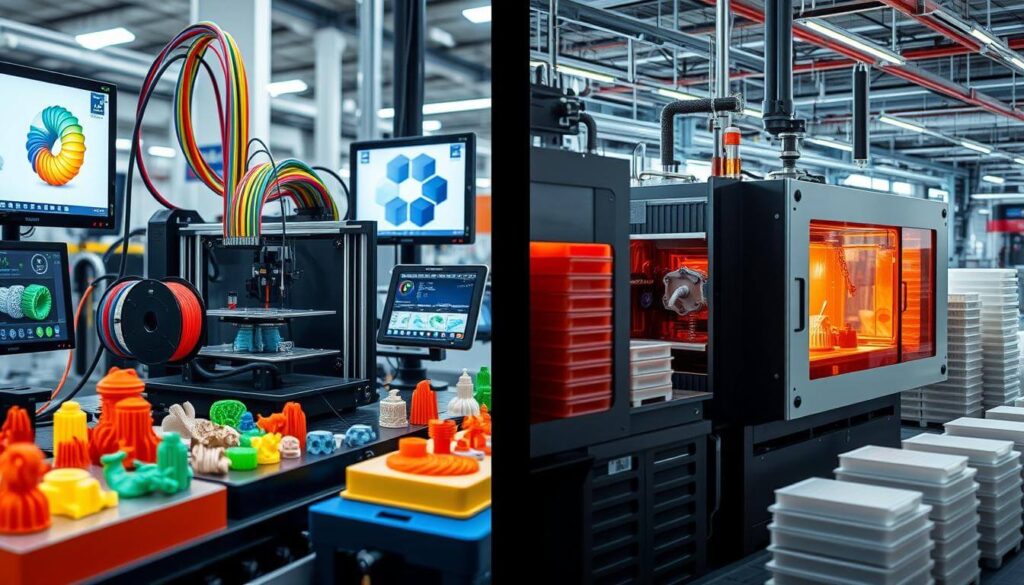

Techniques de fabrication changent toujours. Deux grandes méthodes sont le moulage par injection et l'impression 3D. Savoir comment ils fonctionnent aide à choisir le bon pour vos besoins.

Qu'est-ce que le moulage par injection?

Le moulage par injection est un moyen courant de fabriquer des produits. Il utilise fondu thermoplastique poussé dans un moule. Cela fait des pièces avec la même forme encore et encore.

Comment fonctionne l'impression 3D?

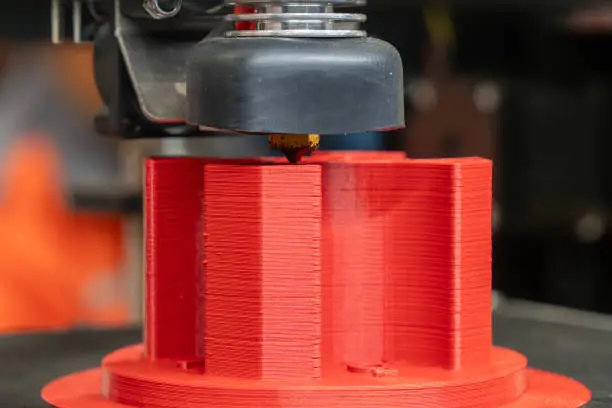

3D L'impression construit des objets couche par couche. Il est également connu comme Modélisation des dépôts fusionnés ou stéréolithmicromographie. Cette méthode fait des pièces complexes sans moule.

Comparaison de processus de base

Le moulage par injection et l'impression 3D font les deux pièces, Mais de différentes manières. Le moulage par injection utilise des matériaux fondus dans un moule. 3L'impression D ajoute des couches pour fabriquer des objets. Chaque méthode a ses propres forces et faiblesses.

| Caractéristiques | Moulage par injection | 3D Impression |

|---|---|---|

| Principe | Injection de fusion thermoplastique en un cavité de moule | Construction en couches d'objets en utilisant fabrication additive techniques |

| Matériels | Large gamme de matériaux thermoplastiques | Variété de matériaux, y compris les plastiques, métaux, et composites |

| Vitesse de production | Volume élevé, production rapide | Relativement plus lent, en fonction de la complexité de la conception |

| Complexité géométrique | Limité par la conception de moisissure | Hautement personnalisable et géométries complexes possible |

Analyse des coûts: Dépenses d'investissement et de production initiales

Lorsque vous regardez l'impression 3D et le moulage par injection, Le coût est essentiel. L'investissement initial et les coûts continus diffèrent beaucoup. Connaître ces différences vous aide à faire un choix intelligent.

Le coûts d'outillage pour les moulures d'injection sont élevées. Faire des moules et des outils coûte beaucoup, De milliers à des centaines de milliers de dollars. 3D Impression, d'autre part, a plus bas Coûts initiaux. Vous dépensez principalement pour l'imprimante 3D et les matériaux.

Mais, Le moulage par injection est moins cher pour faire beaucoup de pièces. Ça devient moins cher à mesure que tu fais plus, grâce à économies d'échelle. En effet, le moulage par injection est efficace et automatisé, Économiser de l'argent en produisant plus.

| Métrique | 3D Impression | Moulage par injection |

|---|---|---|

| Coûts d'outillage | Faible | Haut |

| Coût unitaire | Haut | Faible (à des volumes élevés) |

| Économies d'échelle | Limité | Significatif |

| Volume de production | Convient aux volumes bas à moyens | Idéal pour la fabrication à volume élevé |

Choisir entre l'impression 3D et le moulage par injection dépend de nombreux facteurs. Il s'agit de peser les coûts initiaux, dépenses en cours, Et combien vous prévoyez de produire. Comprendre ces coûts vous aide à choisir la meilleure option pour vos besoins.

Considérations de volume de production et poitrine de seuil de rentabilité

Le volume de production est tout pour décider entre l'impression 3D et le moulage par injection. Les deux méthodes sont préférées par différentes sorties. Comprendre la différence entre la production à faible volume et le haut est crucial pour choisir une meilleure solution pour vos exigences,…

Caractéristiques des coûts de production de la production à faible volume

En petites courses, 3L'impression D doit généralement être préférée à la fabrication traditionnelle. C'est un moyen peu coûteux et rapide de produire une pièce petite ou spécifique. Contrairement aux moulures d'injection, 3L'impression D n'a pas besoin de l'outillage de moisissure coûteux permettant une production plus petite.

Le faible volume

Économie manufacturière

Le moulage par injection est plus économique pour la production de masse et les grandes courses avec un gros coût d'outillage de moisissure initial, mais c'est une fraction du coût par unité. Cela permet que la seule façon de produire des pièces en masse efficace est par moulage par injection.

Calculez votre seuil de rentabilité

Déterminez le seuil de rentabilité entre l'impression 3D et le moulage par injection pour décider d'une méthode de fabrication. Pensez au coût initial, Coûts de production, et capacité par lot. Pour déterminer quand les coûts sont égaux est le volume de production d'or où les objectifs de votre entreprise et les plans d'optimisation des coûts peuvent prendre une décision sur.

“Trouver le bon équilibre entre le volume de production, coût, Et l'efficacité est la clé pour débloquer le plein potentiel de votre processus de fabrication.”

Flexibilité de conception et complexité géométrique

Le développement de produits nécessite des conceptions détaillées et des formes personnalisées. 3D Impression, Les moulures d'injection ont vraiment leur propre truc dans ce.

L'impression 3D excelle à fabriquer des pièces avec des géométries trop complexes pour les autres. Impression ligne par ligne: Bon pour les formes et les conceptions ultra détaillées, il convient aux prototypes instantanés et à quelques lots personnalisés ici.

Moule trop de la même chose avec le moulage par injection mieux pour créer des points communs en forme. Fonctionne bien pour les solides formes. Faire des moules pour le moulage par injection coûte cher et prend du temps. Cela signifie qu'il est difficile pour une modification accélérée de la conception ou du développement de produits.

| Fonctionnalité | 3D Impression | Moulage par injection |

|---|---|---|

| Géométries complexes | Excellent | Limité |

| Flexibilité de conception | Haut | Modéré |

| Personnalisation | Haut | Faible |

| Rapide Prototypage | Avantageux | Moins approprié |

Choisir entre l'impression 3D et le moulage par injection dépend des besoins du projet. Le niveau de complexité et le volume de production est essentiel. Connaître les forces de chaque méthode aide à choisir la meilleure option.

Sélection et propriétés des matériaux

Choisir les bons matériaux est la clé de la fabrication. Cela affecte la façon dont un produit fonctionne, dure, et les coûts. L'impression 3D et le moulage par injection ont de nombreux matériaux à choisir. Chacun a ses propres forces et faiblesses.

Matériaux disponibles pour l'impression 3D

3L'impression D a beaucoup grandi, Permettre de nombreux matériaux. Vous pouvez utiliser thermoplastique, résines, Et même poudres métalliques. Ces matériaux varient en résistance au matériau, durabilité, et résistance à la chaleur. Cela les rend bons pour de nombreuses utilisations.

- Thermoplastique: Utilisé dans l'impression FDM 3D, thermoplastique comme PLA, Abs, et les PETG sont communs. Ils offrent de bonnes performances et sont faciles à trouver.

- Résines: L'impression SLA et DLP 3D utilise la photosensible résines. Ils donnent une grande précision et des finitions détaillées.

- Poudres métalliques: Impression en métal 3D, comme SLS ou DMLS, rend les pièces solides et durables.

Options de matériaux de moulage par injection

Le moulage par injection utilise une large gamme de matériaux, y compris les thermoplastiques, résines, et les métaux. Le choix du matériel dépend des besoins du produit et des performances souhaitées.

| Matériel | Avantages | Désavantage |

|---|---|---|

| Thermoplastique | Rentable, polyvalent, et largement disponible | Limité résistance au matériau et résistance à la chaleur par rapport à d'autres options |

| Thermosets | Excellent durabilité et résistance à la chaleur | Coût plus élevé et processus de fabrication plus complexe |

| Alliages métalliques | Exceptionnel résistance au matériau et durabilité | Nécessite un équipement spécialisé et des coûts de production plus élevés |

Comparaison des performances des matériaux

Lors de la sélection d'une méthode de fabrication, Pensez aux besoins matériels de votre produit. 3L'impression D a plus d'options, Mais le moulage par injection offre plus pour les besoins spéciaux. Connaître les différences aide à choisir la meilleure façon de fabriquer votre produit.

Vitesse de production et temps de marché

Le choix entre l'impression 3D et le moulage par injection affecte la vitesse de fabrication et le temps de commercialisation. Chaque méthode est délai de plomb et efficacité de production sont la clé. Ils aident à décider de la meilleure approche pour votre entreprise, Surtout pour les projets urgents.

3D Impression, ou prototypage rapide, est idéal pour faire petit, pièces personnalisées rapidement. Son processus additif permet aux concepteurs et aux ingénieurs accélérer leurs idées. C'est super utile pour Projets sensibles au temps ou quand vous devez apporter des modifications souvent.

| Facteur de comparaison | 3D Impression | Moulage par injection |

|---|---|---|

| Délai de plomb | Généralement plus court en raison de l'élimination des exigences d'outillage | Plus long délai de plomb, Comme la création de moisissures peut prendre plusieurs semaines |

| Cycle de fabrication | Plus rapide, Comme les pièces sont construites couche par calque | Ralentissez, Comme le processus de moulage par injection implique plusieurs étapes |

| Efficacité de production | Adapté à un faible volume, production personnalisée | Très efficace pour le volume élevé, production standardisée |

D'autre part, Le moulage par injection est le meilleur pour faire beaucoup de la même chose. C'est efficace et rentable pour les grandes commandes. Mais, il faut plus de temps pour s'installer et n'est pas idéal pour Projets sensibles au temps ou changements rapides.

Donc, Le fait d'utiliser l'impression 3D ou le moulage par injection dépend de vos besoins. Considérez combien vous allez gagner, La complexité du design, Et à quelle vitesse vous en avez besoin. Connaître les avantages et les inconvénients de chacun vous aide à choisir judicieusement et à faire commercialiser votre produit plus rapidement.

Comparaison de qualité et de finition de surface

L'impression 3D et le moulage par injection ont leurs propres forces en ce qui concerne la qualité et la finition de surface. Connaître les différences de qualité de surface et de besoins de post-traitement peut vous aider à choisir la bonne méthode pour votre projet.

Normes de qualité de surface

Le moulage par injection fait généralement des pièces avec une finition plus lisse que l'impression 3D. En effet. Il en résulte une surface sans lignes.

3D Pièces imprimées, cependant, pourrait montrer lignes et avoir un plus rude rugosité de surface. C'est parce que l'impression 3D ajoute des couches une à la fois.

Exigences de post-traitement

Pour obtenir une finition de haute qualité sur des pièces imprimées en 3D, Vous pourriez avoir besoin de ponceau, polonais, ou utiliser le lissage de vapeur. Ces étapes peuvent augmenter le temps et le coût de la réalisation de la pièce. Pièces moulées par injection, cependant, ont souvent besoin de moins de travail après leur fabrication.

Choisir entre l'impression 3D et le moulage par injection dépend de ce dont vous avez besoin. Tu devrais penser à contrôle de qualité, précision dimensionnelle, Et à quoi ressemble la pièce. Connaître les différences entre ces méthodes peut vous aider à faire le meilleur choix pour votre projet.

Impact environnemental et durabilité

De nombreuses entreprises essaient de réduire leur empreinte plus petite dans l'environnement. Moulage par injection vs impression 3D - le choix est clair. Ils nuisent également à chacun de la réduction des déchets et de la consommation d'énergie ainsi que de la recyclabilité.

Bien que vous puissiez faire beaucoup de pièces avec moulage par injection, mais il est plein de déchets pour le plastique. En revanche, 3L'impression est plus écologique. Vous obtenez la conception et construisez au besoin pour réduire les déchets de matériaux, permet qu'il soit possible de faire des pièces comme vous avez besoin.

En termes de consommation d'énergie, 3L'impression D nécessite beaucoup moins que le moulage par injection généralement. Cela implique que les marchandises créées avec l'impression 3D pourraient avoir moins une empreinte de carbone.

La capacité de recyclage n'est pas si facile avec ces deux méthodes également. Les matériaux utilisés dans la moulure d'injection peuvent rendre plus difficile de recycler les pièces qu'il produit. Cependant, De nombreuses pièces imprimées en 3D peuvent être fabriquées à partir de matière organique recyclée ou même et tout simplement plus sainitaire également.

L'impact environnemental de ces méthodes varie beaucoup, Basé sur l'application, les matériaux utilisés et le vert de votre producteur. Considérer les déchets et l'énergie ainsi que les compromis de recyclabilité permet aux entreprises de prendre des décisions qui favorisent leurs objectifs de durabilité.

“La fabrication durable n'est plus un luxe - c'est une nécessité pour les entreprises qui veulent prospérer au 21e siècle.”

Entretien et considérations à long terme

Choisir entre l'impression 3D et le moulage par injection signifie examiner les coûts à long terme et l'entretien. Ces aspects affectent grandement le rendement de votre investissement et le coût total de l'utilisation de votre méthode de fabrication.

Exigences de maintenance des outils

Le moulage par injection nécessite des moisissures et un entretien d'outillage réguliers pour la qualité et la longévité. Cela comprend le nettoyage, lubrifiant, et vérifier l'usure. D'autre part, 3D Les imprimantes ont besoin de moins de soins, nettoyer principalement les buses et remplacer le filament.

Durée de vie de l'équipement

Les machines de moulage par injection peuvent durer 10-20 ans ou plus. Mais les moules et les outils peuvent nécessiter un remplacement fréquent. 3D imprimantes, cependant, avoir une vie plus courte, durable 5-10 années avant d'avoir besoin d'une grande mise à jour ou d'un remplacement.

Coûts opérationnels en cours

| Facteur de coût | 3D Impression | Moulage par injection |

|---|---|---|

| consommation d'énergie | Modéré | Haut |

| Coûts des matériaux | Généralement plus élevé | Généralement plus bas |

| coûts de main-d'œuvre | Généralement plus bas | Généralement plus élevé |

Il est essentiel de comprendre les coûts et l'efficacité continus de votre processus. En considérant ces facteurs, Vous pouvez faire un choix qui correspond à vos objectifs de production et à votre stratégie commerciale.

FAQ

3D L'impression et le moulage par injection diffèrent dans la façon dont ils font les choses. 3D L'impression ajoute des couches pour créer des objets. Le moulage par injection utilise des moules pour injecter du matériau fondu dans une cavité.

3L'impression D est idéale pour sa flexibilité dans la conception et sa capacité à faire des formes complexes. Il est également rapide pour les prototypes et permet des pièces personnalisées. Plus, C'est moins cher à l'avance que le moulage par injection.

Le moulage par injection est le meilleur pour fabriquer beaucoup de pièces rapidement et à moindre coût. Il garantit que les pièces sont cohérentes et de haute qualité. Il fonctionne également avec de nombreux matériaux, y compris les plastiques, métaux, et céramique.

Pour faire quelques parties, 3L'impression D est moins chère car elle n'a pas besoin de moules. Mais, Au fur et à mesure que vous faites plus de pièces, Le moulage par injection devient moins cher. C'est mieux de faire beaucoup de pièces.

3L'impression D peut utiliser des plastiques, métaux, céramique, et composites. Le moulage par injection utilise principalement des plastiques mais peut également utiliser certains métaux et céramiques.

Les pièces moulées par injection ont une finition plus lisse que celles imprimées en 3D. Mais, Vous pouvez améliorer les pièces imprimées en 3D avec du ponçage, polissage, ou revêtement.

3L'impression D est meilleure pour l'environnement car il utilise moins de matériel et produit moins de déchets. Le moulage par injection utilise plus d'énergie mais peut recycler plus de matériaux.

Besoins de moulage par injection entretien de moisissure et remplacement, Ce qui coûte beaucoup. 3L'impression D a des coûts de maintenance inférieurs, mais ses machines pourraient ne pas durer aussi longtemps.

3L'impression D est utilisée pour les prototypes rapides, petits lots, et des pièces personnalisées dans de nombreux domaines. Le moulage par injection est le meilleur pour fabriquer beaucoup des mêmes pièces en plastique pour les voitures, électronique, Et plus.

3 pensées