Injection molding is a key method for making lots of plastic parts quickly and accurately. Mais, designing molds for injection molding comes with its own set of problems. These issues affect the quality, how well the parts work, and how much they cost. We will look at the common problems in mold design and how to solve them.

One big worry is avoiding defects like sink marks, warpage, and air traps. These can make parts look bad and not work right. It’s also important to make sure the mold cools evenly and material flows well. This helps make parts the same quality and cuts down on how long it takes to make them.

Getting the gate placement right, designing the runner system, and managing heat are key to making good parts. By tackling these issues, makers can cut down on waste, work faster, and make parts that meet many different needs.

Understanding Core Challenges in Plastic Part Design

Designing plastic parts is complex. You need to pick the right plastic material properties. You also have to think about design constraints et cost-effective molding. Each step has its own set of challenges.

Material Selection and Behavior Analysis

Choosing the right plastic material is key. It affects the part’s strength, résistance à la chaleur, and looks. You must analyze how the material behaves under different conditions.

Things like shrinkage, warpage, and chemical resistance are important. They help avoid expensive mistakes.

Design Requirements and Specifications

- Identify the functional, structural, and aesthetic requirements for the plastic part.

- Establish clear design specifications that address factors like dimensional tolerances, surface finish, and part integration.

- Collaborate with stakeholders to align design objectives with overall product goals.

Cost Optimization Strategies

Keeping costs down is crucial in plastic part design. Ways like part consolidation and smart material choices can help. By balancing cost, qualité, and performance, designers can make cost-effective molding solutions.

“Successful plastic part design requires a comprehensive understanding of material behavior, design requirements, and cost optimization strategies.”

Critical Aspects of Part Quality and Performance

In injection molding, getting the right surface finish, précision dimensionnelle, and structural integrity is key. These factors affect the product’s quality, performance, and how well it works.

Creating a perfect surface finish is a challenge. It depends on the mold design, material choice, and molding process. A smooth surface looks better and lasts longer.

Keeping dimensional accuracy is also vital. It ensures parts fit right and work well together. This is crucial in industries like cars, planes, et les dispositifs médicaux.

| Aspect | Importance | Key Considerations |

|---|---|---|

| Surface Finish | Enhances aesthetic appeal and user experience | Mold design, material selection, molding process optimization |

| Dimensional Accuracy | Ensures perfect fit, minimizes assembly issues, and guarantees interchangeability | Tight tolerance control, process parameters, mold design |

| Structural Integrity | Ensures part durability, reliability, and long-term performance | Material selection, mold design, stress analysis, Optimisation du processus |

Structural integrity is what makes a part last. It depends on the material, mold design, and how it’s made. This ensures the part is strong, reliable, and works well over time.

By focusing on these key areas during mold design, makers can create parts that are not just good but great. They meet high standards of quality, function, and reliability.

Addressing Flow and Filling Issues in Injection Mold Design

Getting melt flow right is key in injection mold design. Melt flow analysis helps spot problems and improve the design. This ensures the mold fills evenly. Gates, where plastic flows in, are crucial for this.

Gate Location Optimization

Choosing the right gate spot is vital. It affects melt flow and part quality. The gate should help flow evenly, avoiding defects. Part shape, épaisseur de paroi, and material are important here.

Runner System Design

The runner system is key for a good injection molding process. A balanced runner system ensures even filling. This prevents defects like short shots and sink marks. Designing the runner system well needs careful analysis.

Weld Line Prevention

Weld lines can harm a part’s look and strength. To avoid them, improve gate placement and adjust melt temperature and speed. Adding mold features can also help. This way, parts come out looking and feeling great.

| Technique | Avantages |

|---|---|

| Melt Flow Analysis | Identifies potential issues and optimizes the design for efficient filling |

| Gate Location Optimization | Promotes balanced and even melt flow, minimizing defects |

| Runner System Design | Ensures consistent and uniform filling, preventing issues like short shots and sink marks |

| Weld Line Prevention | Maintains the aesthetic and structural integrity of the molded part

|

By focusing on flow and filling in mold design, makers can create top-notch plastic parts. These parts meet all the needed specs and perform well.

Thermal Management Solutions for Mold Efficiency

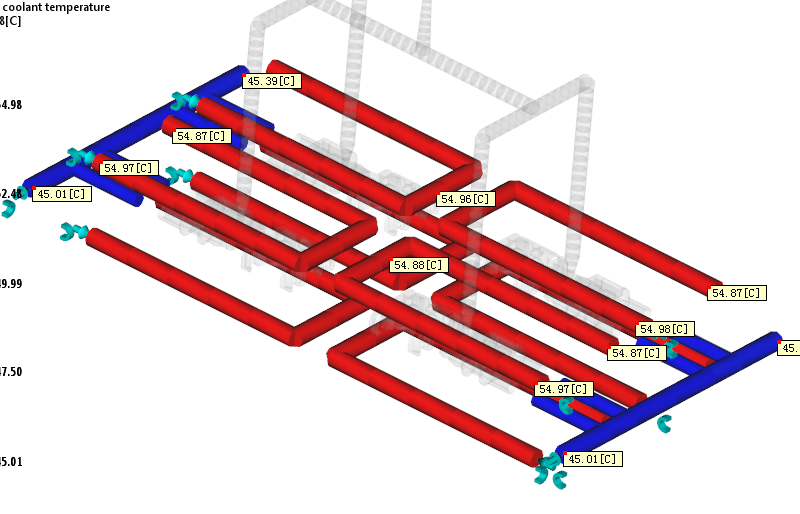

Effective thermal management is key in injection mold design. It affects the whole manufacturing process’s efficiency and performance. Two important areas to focus on are cooling channel design et heat transfer optimization.

Cooling channel design is vital for consistent part quality and shorter cycle times. By placing and shaping cooling channels wisely, manufacturers can keep mold temperatures even. This prevents warpage, sink marks, and other defects. Advanced tools help optimize cooling channel layouts for better efficiency.

Heat transfer optimization is also crucial for mold efficiency. Choosing the right materials, surface finishes, and coolant flow rates boosts the mold’s heat absorption and release. This reduces cycle time and increases production speed.

- Implement innovative cooling channel design strategies to ensure uniform temperature distribution

- Optimize heat transfer through careful material selection and coolant management

- Leverage simulation tools to fine-tune the thermal management system for maximum cycle time reduction

“Effective thermal management is the cornerstone of efficient injection mold design. By mastering cooling channel optimization and heat transfer principles, manufacturers can unlock significant improvements in part quality and production speed.”

By taking a comprehensive approach to thermal management, injection mold designers can tackle major challenges. They can create high-performance, cost-effective solutions that meet the industry’s changing needs.

Resolving Common Defects in Injection Molded Parts

Ensuring high-quality injection molded parts is key for manufacturers. Defects like sink marks, warpage, air traps, and flash can happen during molding. Mais, there are ways to fix these problems and improve part quality.

Sink Marks and Warpage Prevention

Sink marks are small depressions, and warpage makes parts distorted. To avoid these, focus on mold design and process tweaks. Adjust gate placement, épaisseur de paroi, and cooling systems to keep parts perfect.

Air Trap Elimination

Air traps cause voids and defects. Use vents, size runners right, and choose smart gating to remove air. This ensures parts are fully filled and of high quality.

Flash Prevention Techniques

Flash is excess material outside the mold. Use the right mold clamping force, precise clearances, and good venting. These steps help reduce flash and meet quality standards.

Things like shrinkage, warpage, and chemical resistance are important. They help avoid expensive mistakes.