射出成形プラスチック成分は、自動車エンジン部品から救命医療機器まで、精度と信頼性を要求する産業のバックボーンです. GHXLD型で, 耐久性は単なる仕様ではないことを理解しています; それは卓越性へのコミットメントです. このガイドは、製品の寿命を最大化するための高度な戦略を掘り下げています, 数十年のエンジニアリングの専門知識と最先端のテクノロジーを組み合わせる.

1. 物質科学: 極端な条件のためのエンジニアリングポリマー

なぜそれが重要なのか: 以上 60% プラスチックコンポーネントの早期障害の最適ではない材料の選択に由来する (ソース: プラスチックエンジニアリングジャーナル, 2022).

GHXLD金型のアプローチ:

高性能ポリマー:

- ピーク (ポリエーテルエーテルケトン):

- アプリケーション: 航空宇宙燃料システム, 手術器具.

- プロパティ: 250°Cで引張強度を保持します, 炭化水素に対する化学的不活性.

- PPS (ポリフェニレン硫化物):

- アプリケーション: 電気コネクタ, ポンプハウジング.

- プロパティ: UL94 v-0 炎抵抗, 0.02% 水分吸収.

- PEI (ポリutimide):

- アプリケーション: 滅菌可能な医療トレイ, LEDハウジング.

- プロパティ: 180°C継続的な使用, FDA準拠.

強化された複合材料:

- カーボンファイバー - ポリアミドハイブリッド: 40% 減量対. 同等の剛性を持つアルミニウム.

- アラミッド繊維強化ペット: 耐衝撃性 15 KJ / (ISO 179), 保護ギアに最適です.

持続可能な材料ソリューション:

- 産業革命後のリサイクルブレンド: 50% 自動車のトリムパーツのリサイクルコンテンツ.

- バイオベースのポリマー: PA610 (60% キャスターオイル由来) 環境に配慮した家電用.

2. 金型デザイン: ソースでの障害を排除します

業界の課題: 35% カビ関連の欠陥の熱応力と不均一な冷却から生じる (ソース: Society of Plastics Engineers).

Ghxld Moldの革新:

AI駆動型シミュレーション:

- Moldflow®予測分析: ゲートの場所を最適化します, せん断誘発分解を減らす 25%.

- トポロジの最適化: 軽量を生成します, コンフォーマル冷却チャネルを備えた高剛性カビ構造.

高度な冷却技術:

- 3Dプリントコンフォーマル冷却: Reduces cycle time by 18–22%.

- Variable-Temperature Molding (VTM): Eliminates flow lines in optical-grade PMMA.

Ejection System Engineering:

- Gas-Assisted Ejection: Prevents part deformation in deep-cavity molds.

- Collapsible Cores: Enables undercut-free demolding of threaded inserts.

3. Process Optimization: Precision Beyond Industry Standards

Key Parameters:

- Melt Temperature Control: Real-time viscosity monitoring for PEEK processing (385–400°C).

- Injection Profiling: Multi-stage velocity control to optimize filling and packing.

- Vacuum-Assisted Molding: Eliminates air traps in microfluidic chips.

4. Post-Processing: Tailored Solutions for Extreme Environments

GHXLD Mold’s Capabilities:

- Surface Enhancement: Diamond-Like Carbon (DLC) coatings for hydraulic valve seals.

- Plasma Polymerization: Deposits parylene films for moisture barriers.

- Overmolding with TPV: Combines rigid PC/ABS cores with soft grips.

- Metal-Plastic Hybrid Molding: Laser-etched steel inserts bonded to LCP for 5G antenna housings.

5. Quality Assurance: Data-Driven Durability Validation

GHXLD Mold’s Testing Regimen:

- Mechanical Performance:

- Fatigue Testing: 2.1 million cycles for PA66 seatbelt buckles.

- Creep Resistance: 1,000-hour testing at 70°C/85% RH for outdoor telecom enclosures.

- Environmental Resilience:

- UV Aging (ISO 4892-2): 3,000-hour xenon-arc exposure simulating 10-year outdoor service.

- Chemical Immersion: 30-day exposure to ASTM Oil #3 for automotive components.

- Digital Twin Verification: ANSYS® Simulation predicts 15-year thermal cycling effects.

6. ケーススタディ: Real-World Durability Transformations

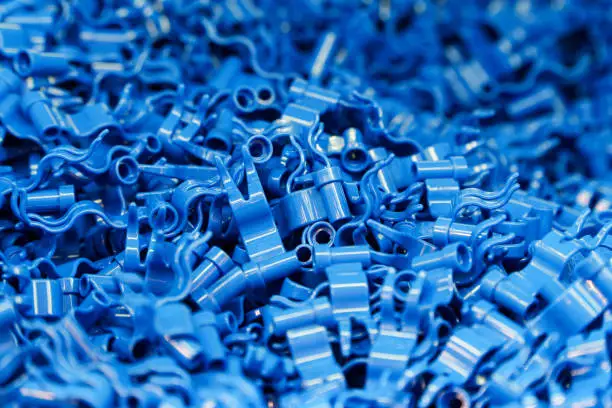

Case 1: High-Speed Railway Cable Clip

Challenge: ナイロン 6 後にクリップが割れました 6 振動による数ヶ月 (IEC 61373 カテゴリ 1). 解決: コンフォーマル冷却およびモールドストレスセンサーを備えたミネラル強化PA66. 結果: 合格した 5 百万の加速サイクル (0–200 Hz).

Case 2: 埋め込み可能な医療機器ハウジング

Challenge: ピークハウジングにはISOが必要です 10993-5 細胞毒性コンプライアンス.

解決: クリーンルームモールディング (ISOクラス 7) エレクトロポーリングツール付き.

結果: ゼロ微粒子 >5µm, 100% 生体適合性認証.

Case 3: 航空宇宙センサーエンクロージャー

Challenge: 極端な高度に耐える必要がありました (-60°C〜120°C).

解決: UV耐性コーティングと極低温アニーリングを備えたPPS.

結果: Maintained structural integrity after 1,500 thermal cycles.

Case 4: Consumer Electronics Wearable Housing

Challenge: Enclosure required IP68 waterproofing while maintaining lightweight properties.

解決: Overmolded LSR (液状シリコーンゴム) with precision sealing.

結果: Surpassed 100,000 flex cycle tests without failure.

Why Partner with GHXLD Mold?

- End-to-End Expertise: From material selection to final inspection, we optimize every step.

- Innovation-Driven: Cutting-edge mold design, AI-driven simulations, and advanced cooling strategies.

- Sustainability Commitment: 30%+ recycled content in select projects without durability trade-offs.

- Industry-Leading Quality Assurance: Rigorous testing ensures components exceed performance expectations.

結論

Enhancing the durability of injection molded products demands technical precision, 革新, and relentless quality control. At GHXLD Mold, we combine cutting-edge technology with decades of expertise to deliver components that exceed industry standards.

Ready to Elevate Your Product’s Lifespan?

Contact GHXLD Mold for a customized durability optimization plan.