What is LSR Molding?

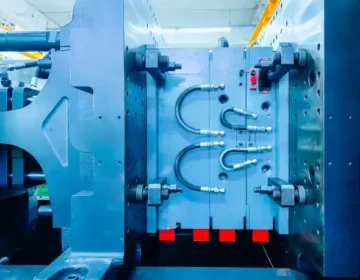

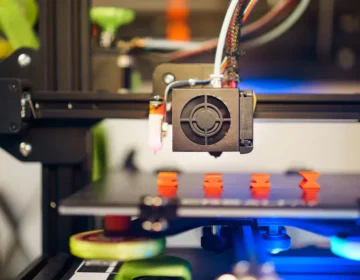

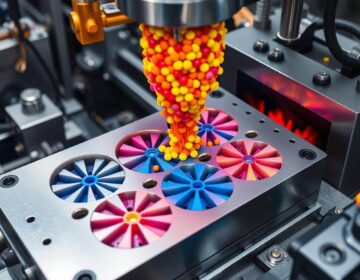

LSR molding involves injecting a two-component liquid silicone rubber into a precisely designed mold cavity. Unlike traditional solid silicone rubber, LSR is a liquid system that is injected at high pressure, where it cures into a solid, flexible silicone material. This process is highly effective for creating complex, lightweight parts with micron-level accuracy, making it particularly valuable for industries that demand precision and durability.

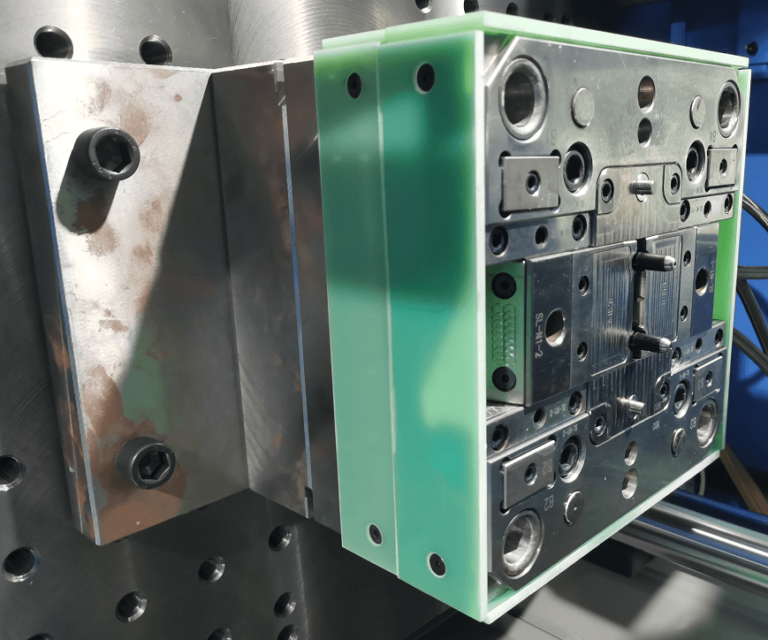

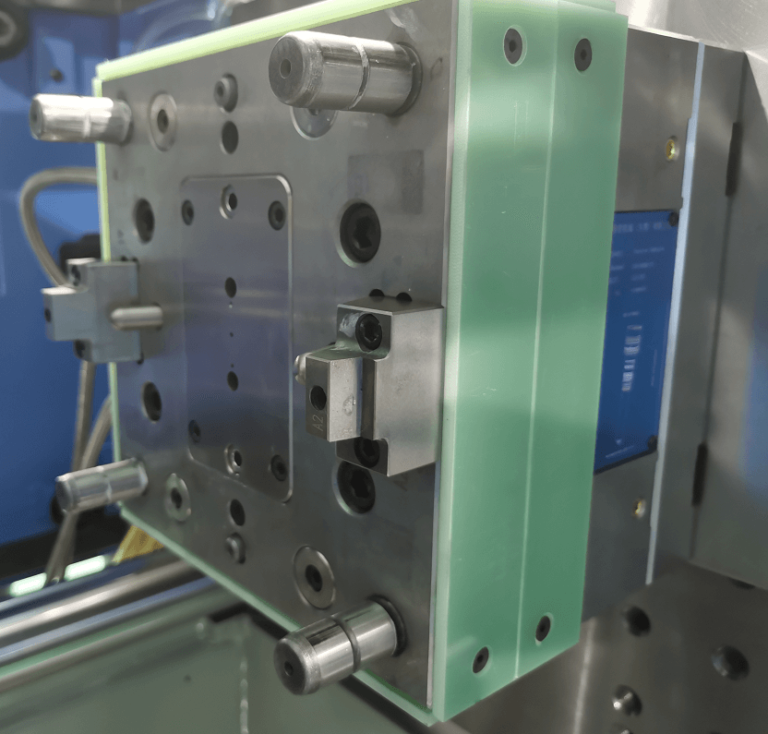

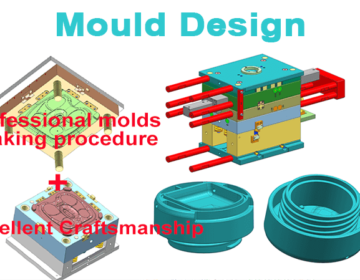

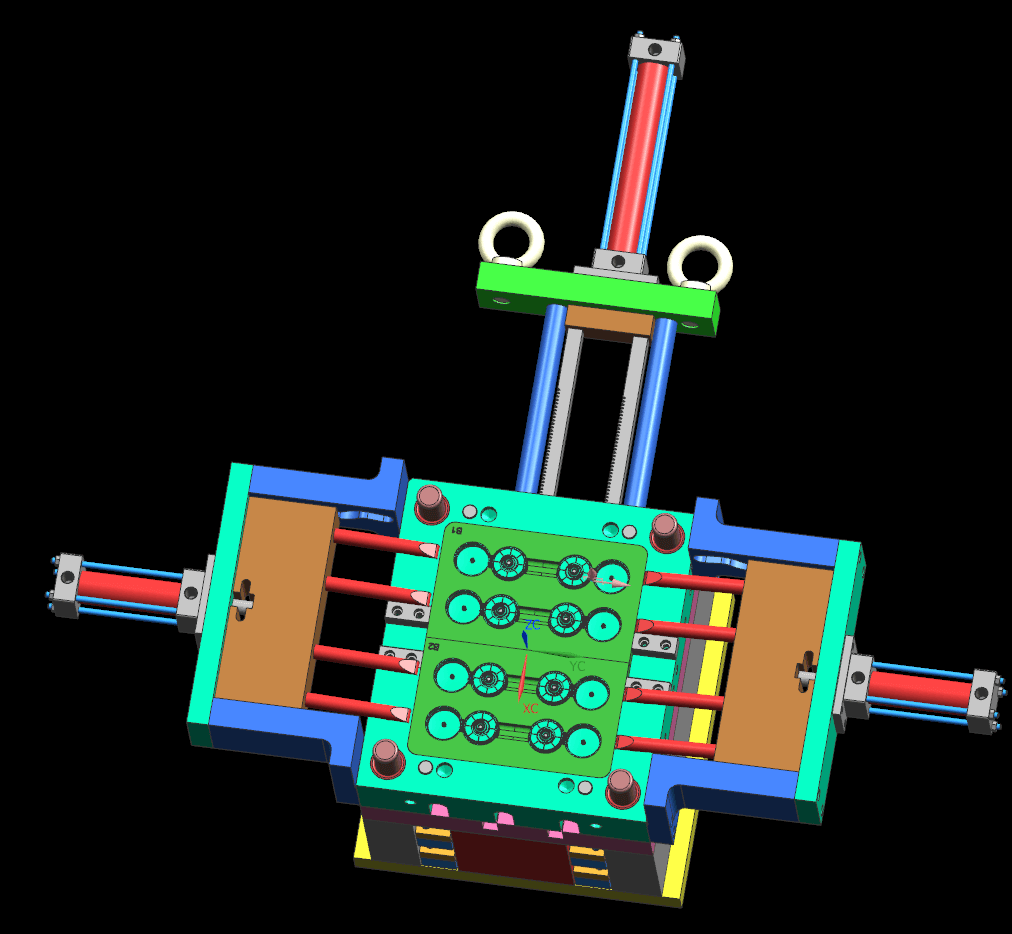

Mold application – LSR mold

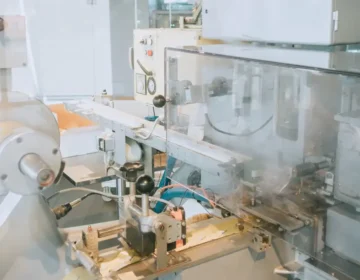

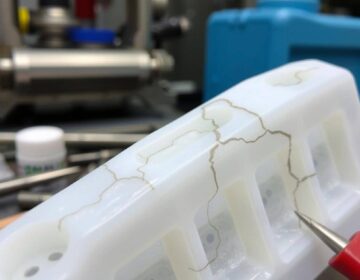

Provide molds for liquid silicone products such as medical grade protective masks, surgical silicone sleeve accessories and so on

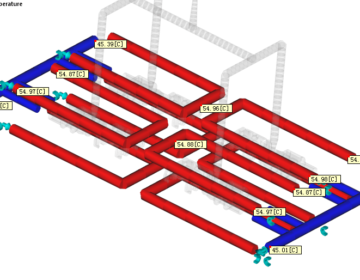

- Through high and low temperature design, the problem of TPU scald of the first beer is solved

- Use unique sealing method to reduce the pressure at PL

- Independently developed cold runner technology

- Unique post-treatment bonding method

LSR Molding (液状シリコーンゴム成形品) – Precision, 汎用性, and Durability

Overview of LSR Molding

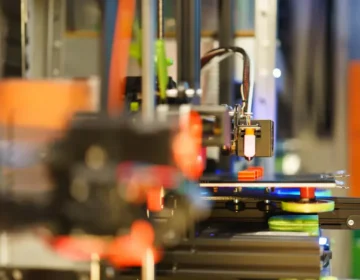

At GHXLD, we specialize in high-quality injection molding services, including Liquid Silicone Rubber (LSR) molding. Our state-of-the-art LSR mold technology and precise molding processes ensure that we deliver products that meet the highest standards of quality, precision, and performance. Here’s how we excel in the LSR mold application and why GHXLD is the preferred choice for your molding needs.

Why GHXLD is Your Trusted Partner for LSR Molding

GHXLD is not just another molding supplier. We are a partner that brings over 12 years of expertise, cutting-edge technology, and a commitment to quality at every step of the production process. Our LSR molding services offer unparalleled precision, customization, and scalability, allowing us to meet your specific needs whether for medical devices, automotive parts, or other precision components.

By choosing GHXLD for your LSR molding needs, you gain access to high-quality products, technical expertise, and a dedicated team that understands the unique demands of your industry.

For more information or to request a quote, contact GHXLD today and let us help bring your projects to life with the precision and quality that only advanced LSR molding can offer.

We're Supplier,

部品をオンラインで注文する準備ができました?

お気軽にお問い合わせください。ニーズを送信してください