What is an Injection Mold Parting Line?

The injection mold parting line is the visible line on a molded product where two halves of the mold meet. This line is formed due to the slight gap between the cavity and core of the mold, which allows the molten plastic to take shape before cooling and solidifying.

Understanding and properly designing the parting line is crucial for achieving high-quality molded parts, as it affects aesthetics, functionality, and manufacturability. 不十分に設計された別れのラインは、フラッシュフォーメーションなどの欠陥につながる可能性があります, ミスアライメント, そして、弱い構造的完全性, 製品のパフォーマンスに影響を与え、生産コストを増やすことができます.

射出成形における分離ラインの種類

射出成形では、いくつかのタイプの別れのラインが一般的に使用されています, 製品の設計と金型構造に応じて:

- まっすぐな別れのライン - シンプル, 2つのカビの半分が出会う平らな線, 対称部品に一般的に使用されます. It is the easiest to manufacture and results in minimal tooling complexity.

- Stepped Parting Line – Involves a step-like offset to accommodate complex shapes and prevent parting misalignment. This type is often used in products requiring different wall thicknesses.

- Curved Parting Line – Designed for parts with irregular shapes, ensuring a smooth transition and minimal visible lines. This is ideal for aesthetic components where a seamless appearance is required.

- Angled Parting Line – Used for tapered or inclined surfaces, helping to improve the mold release process. This design helps reduce defects in undercut areas.

- Complex Parting Line – Applied to intricate designs requiring multiple draft angles and specialized mold construction. These are commonly seen in automotive and consumer electronics parts.

Factors Affecting the Parting Line Placement

The placement of the parting line is determined by several factors, 含む:

- Aesthetic Considerations: A well-placed parting line can minimize the visibility of seams and improve the overall appearance of the part.

- Moldability: Ensuring easy ejection of the part from the mold without causing defects such as warping or stress marks.

- Tooling Complexity: Simpler parting lines reduce mold manufacturing costs and improve durability, whereas complex parting lines may require additional machining and fine-tuning.

- Functional Requirements: Some products require specific parting line placements to maintain mechanical strength or sealing properties. 例えば, in medical devices, the parting line should not interfere with critical sealing surfaces.

- Flash Formation: Proper design minimizes unwanted material seepage along the 別れの行, reducing post-processing requirements and improving dimensional accuracy.

Common Defects Related to Poor Parting Line Design

Improper parting line placement can lead to several issues, 含む:

- Flash: Excess plastic material that seeps out through the parting line gap, requiring secondary trimming operations.

- Mold Misalignment: Incorrect positioning of the mold halves, leading to offset features on the final product.

- Weak Structural Integrity: Poorly designed parting lines can cause weak points, reducing the product’s durability.

- Aesthetic Imperfections: Visible seam lines can negatively impact the visual appeal of the molded part.

How to Optimize Parting Line Design

To achieve optimal results, consider the following best practices when designing parting lines:

- Early Design Consideration: Address parting line placement during the initial product design phase to avoid manufacturing complications.

- Collaboration with Mold Designers: Working closely with experienced mold designers ensures an efficient and cost-effective solution.

- Utilizing Advanced CAD Software: Modern design tools help simulate mold flow and analyze the best parting line positions.

- Precision Machining Techniques: High-precision CNC machining EDMテクノロジーは、分割線の精度を向上させます.

- 金型の定期的なメンテナンス: 金型がよく維持されていることを保証すると、摩耗や裂傷が防止され、それが別れのラインに沿って欠陥につながる可能性があります.

- 材料の選択: 適切な材料を選択することは、分割線の動作に影響を与える可能性があります. より柔らかい材料は、フラッシュを防ぐためにより狭いカビの許容範囲を必要とするかもしれません.

- プロトタイプテスト: プロトタイプの作成により、メーカーは大量生産前に分割線の影響をテストできます, 後で費用のかかる修正を減らします.

Industry Applications and Case Studies

Optimizing the parting line is critical in several industries. Below are real-world examples demonstrating the importance of precision in parting line design:

- Automotive Industry – High-Precision Interior Components

A leading automotive manufacturer required ultra-precise injection-molded dashboard components with minimal visible seam lines. By leveraging advanced CAD simulations and CNC machining, GHXLD Precision Mould was able to optimize the parting line placement, フラッシュを大幅に削減し、最終的な審美品質を向上させます. - 医療機器 - シームレスシリンジの生産

医療機器の製造, スムーズに達成します, 汚染のない表面が最重要です. GHXLDは、注射器生産会社のために高精度の射出型を開発しました, 別れのラインが重要なシーリングエリアから離れて配置されたことを確認します, したがって、製品の信頼性と安全性が向上します. - 家電 - スマートフォンのケーシング

大手電子機器ブランドが必要です シームレス, 高光沢プラスチックケース for its premium smartphone models. GHXLD utilized precision EDM and advanced mold surface treatments to achieve a nearly invisible parting line, reducing the need for additional finishing processes and improving production efficiency. - Packaging Industry – Thin-Walled Food Containers

In food packaging, maintaining uniform thickness and minimizing flash is essential. GHXLD designed custom high-speed injection molds with optimized parting lines, reducing material waste and ensuring tight-fitting lids for secure packaging.

GHXLD Precision Mould – Your Trusted Partner in Injection Molding

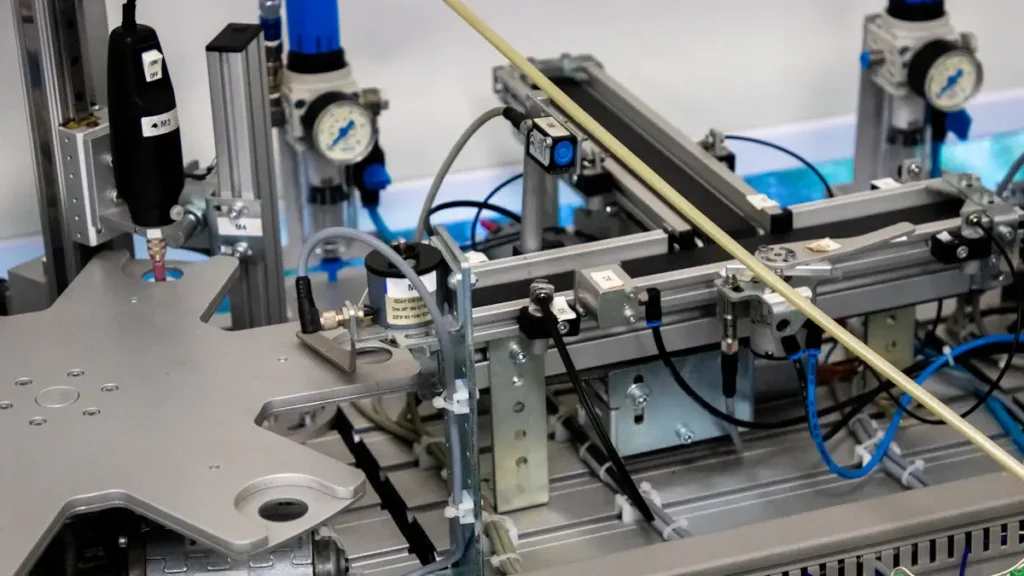

At GHXLD Precision Mould Co., 株式会社., we specialize in designing and manufacturing high-quality precision injection molds with meticulously engineered parting lines. Our expert team utilizes advanced CNC加工, EDM, and CAD software to optimize mold design for efficiency and superior product quality.

With extensive experience in automotive, 医学, and consumer electronics industries, we provide tailored mold solutions that meet the highest precision standards. Our commitment to 革新, quality, and customer satisfaction ensures that you receive the best-in-class injection molding services.

Whether you need custom injection molds or expert consultation on mold design, GHXLD Precision Mould is your reliable partner. Contact us today to discuss your project needs and achieve the best manufacturing solutions.

Visit us at xld-mould.com to learn more!

With extensive experience in automotive, 医学, and consumer electronics industries, we provide tailored mold solutions that meet the highest precision standards. Our commitment to innovation, quality, and customer satisfaction ensures that you receive the best-in-class injection molding services.