The world of injection molding is complex and fascinating. It involves many intricate components working together. These components create the precise plastic parts we use daily. In this guide, we’ll explore the key parts of the injection molds. We’ll see how they work together to make high-quality plastic parts.

The injection molding process centers around the mold. It’s a tool engineered to shape molten plastic into the right form. This tool is made of different specialized parts. Each part is vital for making plastic parts that meet high standards.

By understanding these mold components, we appreciate the engineering behind plastic manufacturing. Let’s dive into the injection mold and discover how everyday products are made.

Key Takeaways

- Injection molds is a complex system of different dedicated pieces

- Every single component is very important when successful manufacturing plastic part

- Perfecction of mold components and they are important to get the highest manufacturing efficiency in an injection molding process

- Good design and fit of the components within a mold creates better plastic parts that are more efficient to produce.

- From the ins and outs of injection moulds this article ponders modern manufacturing techniques

- Injection Molding Systems Fundamentals Explained

Understanding the Fundamentals of Injection Molding Systems

The injection molding process is a key method for making many plastic products. It involves the machine and mold working together. Knowing how it works and the importance of mold design is key for making good plastic parts.

Basic Principles of Injection Molding

The process melts thermoplastic materials and pushes them into a mold under high pressure. As it cools, it takes the mold’s shape, making the part. This cycle of heating, injecting, and cooling helps make lots of plastic materials efficiently.

The Role of Mold Components

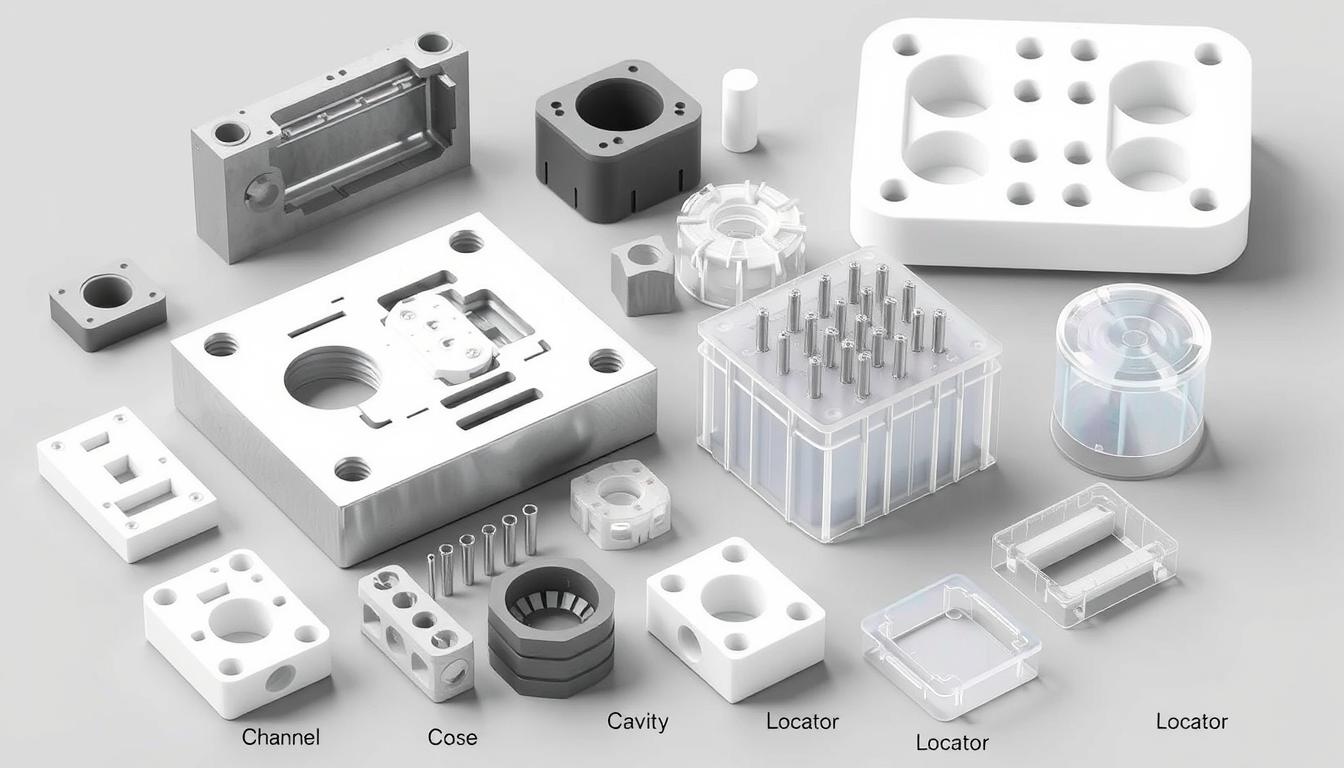

The mold is crucial in injection molding, shaping the final part. It has parts like the core, cavity, runner system, and ejection system. Each part is vital for the right flow, size, and easy part removal.

Material Considerations in Mold Design

- The type of plastic materials used affects the mold design. Each material has its own needs and properties.

- Things like shrinkage, thermal expansion, and viscosity of thermoplastic materials are important. They help design the mold for the best part quality.

- Understanding how materials work with the injection molding process is crucial. It helps in designing the mold and making parts.

“The key to successful injection molding lies in the seamless integration of the machine, mold, and material.”

Knowing the basics of injection molding and the mold’s role helps make high-quality, affordable plastic parts. This meets the changing needs of the industry.

Core and Cavity: The Heart of Injection Molds

At the heart of every injection mold are the mold core and cavity. These parts shape the final product. They are key to the part’s geometry and surface finish. Knowing how they work is vital for quality results.

The mold core makes the part’s internal details. It’s the space that gets filled with plastic. Its design and finish affect the part’s details and quality.

The mold cavity shapes the part’s outside. It’s where the plastic solidifies. Its design and finish are crucial for the part’s shape and surface quality.

The mold core and cavity work together. Their design ensures the part meets shape, size, and surface quality needs. Making them well is key to creating parts that look and perform great.

| Mold Core | Mold Cavity |

|---|---|

| Responsible for internal features and details | Defines the external shape and dimensions |

| Determines part geometry and level of detail | Impacts part geometry and surface finish |

| Negative space for plastic material to fill | Positive form for plastic material to flow into |

Improving the mold core and cavity design is vital. It ensures parts are consistent and of high quality. By understanding their roles, manufacturers can meet part geometry and surface finish needs.

Runner Systems and Gate Design in Injection Molds

In injection molding, runner systems and gates are key. They ensure material flows well and products are top-notch. Let’s explore these mold components in detail.

Types of Runner Systems

Injection molding uses two main runner systems: cold runner and hot runner. Cold runners freeze plastic paths to move molten material to cavities. Hot runners keep material molten, improving flow and cutting waste.

Gate Configurations and Selection

Gates are where molten material enters the mold. They come in types like edge gates, fan gates, submarine gates, and pin point gates. The right gate depends on part shape, material, and look. Good gate design ensures smooth material flow in the mold.

Optimization for Material Flow

- Look at cold runner or hot runner designs to reduce flow resistance and improve material path.

- Place and size gates wisely to ensure even material flow and avoid issues like weld lines or air traps.

- Use CFD simulations to model and improve gate design and material flow in the mold.

- Test and refine the gate design and material flow through experiments to boost efficiency.

| Runner System | Advantages | Disadvantages |

|---|---|---|

| Cold Runner |

|

|

| Hot Runner |

|

|

Knowing about runner systems and gate design helps molders improve material flow. This leads to better products and more efficient production.

“The key to successful injection molding lies in the thoughtful design and integration of the runner system and gate configuration.”

Ejection System Components and Mechanisms

In injection molding, the ejection system is key for removing parts from the mold. This section explores the main parts and how they work together. They are vital for removing parts well and making the process more efficient.

Ejector Pins: The Backbone of Part Removal

Ejector pins push the molded part out of the mold. They are placed in the mold and move in and out at the right times. This ensures the part comes out smoothly without damage.

The right placement and size of these pins are important. They help prevent the part from getting distorted or warped during removal.

Stripper Plates: Ensuring a Clean Separation

Stripper plates are also crucial in the ejection system. They surround the mold and pull the part away as the pins move. This helps the part separate cleanly from the mold.

Air Ejection: A Gentle Approach

Some systems use air ejection to remove parts. This method uses compressed air to lift the part gently. It’s good for delicate or complex parts where you don’t want to cause damage.

Knowing how the ejection system works helps professionals improve their molding process. It reduces defects and makes the cycle more efficient. These parts work together to ensure the product is removed well, setting up a successful manufacturing process.

| Ejection System Component | Function | Key Considerations |

|---|---|---|

| Ejector Pins | Push the molded part out of the mold cavity | Placement, size, and timing for optimal part removal |

| Stripper Plates | Pull the part away from the mold surface | Coordination with ejector pins for clean separation |

| Air Ejection | Gently lift the part off the mold using compressed air | Suitable for delicate or intricate parts |

The ejection system is vital in injection molding for removing parts efficiently. By improving this system, manufacturers can make better products. This leads to higher quality and customer satisfaction.

Cooling Channel Design and Temperature Control

Designing the cooling channel and controlling temperature are key in injection molding. They greatly affect the product’s quality and efficiency. By improving the cooling system, makers can cut down cycle times and make parts more consistent.

Cooling System Layout

The layout of the cooling system in the mold is crucial. It ensures heat is evenly removed. Conformal cooling channels, which match the mold’s shape, are often used. They help avoid hot spots and ensure even cooling.

Temperature Monitoring Solutions

It’s important to watch the mold’s temperature during molding. This helps with heat transfer and cycle time reduction. Thermocouples or infrared sensors can track temperature changes. This lets operators adjust the cooling system for better part quality.

Efficiency Optimization Methods

To boost mold cooling efficiency, several methods can be used. These include:

- Using conformal cooling channels for better heat removal

- Advanced software to design the cooling system

- Adjusting coolant temperature and flow for best heat transfer

- Smart sensors and data analytics for cooling process monitoring

These strategies help reduce cycle time and improve part quality. This boosts productivity and profit for molders.

Guide Pins and Bushings: Ensuring Precise Alignment

Getting high-quality, precision-molded products depends on how well the mold parts line up. Guide pins and bushings are key to this, making sure the mold halves move and position correctly during molding.

Guide pins are set in the mold to help with accurate alignment. They fit into bushings in the other mold half. This setup ensures the mold halves fit perfectly, avoiding any misalignment.

The materials for guide pins and bushings are picked for their wear resistance and mold alignment over time. Hardened tool steel is often used for guide pins. Bushings are made of bronze or PTFE-lined for smooth, precise movement.

Keeping guide pins and bushings in good shape is crucial. Regular checks, cleanings, and replacements of worn parts help keep the mold working well. This ensures consistent quality and efficiency in production.

| Component | Material | Benefit |

|---|---|---|

| Guide Pins | Hardened Tool Steel | Wear Resistance, Precise Alignment |

| Bushings | Bronze, PTFE-Lined | Low Friction, Self-Lubrication |

Understanding the importance of guide pins and bushings in molding is key. It helps manufacturers improve their mold design and care. This leads to consistent, high-quality results and keeps the mold working well for a long time.

Venting Systems for Enhanced Product Quality

In the world of injection molding, venting systems are key to quality. They help avoid air traps and surface defects. These issues can harm the look and function of the product.

Types of Venting Methods

There are many ways to vent an injection mold. Each method has its own benefits and uses. Here are some common ones:

- Ejector pin vents: These are ejector pins that help gas release during molding.

- Parting line vents: Small gaps or grooves along the mold parting line help air and gases escape.

- Vent slots: Narrow slots or channels cut into the mold surface for mold venting.

- Micro-vents: Tiny, almost invisible holes drilled into the mold cavity for precise gas release.

Placement Strategies

Where you place vents is very important. Vents should be in areas where air and gases build up. This includes sharp corners, thin sections, and complex shapes. By planning vent locations well, manufacturers can reduce surface defects and improve product quality.

Maintenance Requirements

Keeping the venting system in good shape is a continuous task. Regular cleaning and checks are needed. This ensures mold venting works well and prevents air traps and gas release problems.

Understanding the role of venting systems is crucial. By following best practices, injection molding experts can make better products. This meets the high standards of their customers.

Support and Clamping Components

In injection molding, keeping the mold stable is key. This is why support and clamping components are so important. They help the mold handle the high pressures and forces of the molding process.

The mold base is the mold’s foundation. It’s strong and reliable, supporting the core and cavity parts. It must handle the clamping force needed to keep the mold halves together during molding.

The support pillars are like vertical stabilizers. They keep the mold stable under the pressure of molten plastic. These pillars are designed to spread the load evenly, avoiding mold distortion or warping.

The clamping system is vital for mold stability. It uses hydraulic or mechanical systems to apply the right amount of force. This creates a tight seal, preventing leaks or flash during injection.

By focusing on these components, mold makers create a strong system for high-volume production. This focus on detail leads to consistent part quality. It also reduces the chance of mold failures or downtime.

Hot Runner Systems and Their Integration

Hot runner systems are changing the game in injection molding. They bring many benefits, like better thermal management and energy use. They also improve part quality and speed up production. Knowing the perks of hot runner tech and how to pick and install components is key for better molding.

Benefits of Hot Runner Systems

Hot runner systems save on material and costs by avoiding cold runner waste. They control temperature well, making parts better and less flawed. Plus, they cut down cycle times, boosting productivity and efficiency.

Component Selection Criteria

Choosing the right hot runner parts is important. You need to think about mold design, material needs, and production goals. The manifold, valve gates, and thermal solutions must fit your specific needs. The right components make the system work better and last longer.

Installation Considerations

Installing a hot runner system right is essential. You must align it well, connect it securely, and set up monitoring and maintenance. Doing this right avoids problems like leaks and uneven heating. It helps keep the molding process efficient and productive over time.

FAQ

An injection molding system has several key parts. These include the mold, the injection unit, and the clamping unit. It also has a cooling system and an ejection system. Together, they help make precise plastic parts.

The core and cavity of a mold are crucial. They decide the part’s shape and finish. The core makes the inside, and the cavity makes the outside.

Injection molds use either cold runner or hot runner systems. Cold runners are solid plastic channels. Hot runners use heated manifolds to keep material flowing.

Ejection system parts like ejector pins and stripper plates help remove parts. They automatically take out the molded part from the mold cavity at cycle end.

Designing cooling channels is key for mold temperature control. It’s about the channel layout, coolant flow, and temperature monitoring. These help reduce cycle times.

Guide pins and bushings ensure mold parts align well. This is vital for making high-quality, precise plastic parts.

Hot runner systems improve material flow and reduce waste. They also speed up cycle times and save energy, beating cold runner systems.

Mold bases, support pillars, and clamping mechanisms are strong. They handle high pressures and forces during molding. This keeps the mold stable and the parts quality high.

5 thoughts