Trusted Medical Injection Mold Manufacturer

Precision LSR & Plastic Molding Solutions for Healthcare & Diagnostics

Product Display

품질은 최선을 다할 만큼 충분한 관심을 기울일 때에만 발생합니다.

우리는 프로토타이핑부터 생산 및 그 이상까지 귀하의 파트너입니다.

무제한 용량

주문형 디지털 공장과 광범위한 제조업체 네트워크를 통해, 용량 문제는 이제 과거의 일입니다.. 일관된 리드타임을 즐기세요, 다양한 플라스틱 및 금속 재료 선택, 그리고 신뢰할 수 있는 공급망. 항상 정시에 배송되는 고품질 부품.

설계 및 엔지니어링 지원

우리는 자동화된 제조 지원과 실시간 제조 지원을 모두 제공합니다.. 각 견적에는 부품 설계를 효율적으로 향상하기 위한 무료 대화형 제조 가능성 분석이 포함됩니다.. 추가 문의사항은, 우리의 애플리케이션 엔지니어는 WhatsApp을 통해 귀하의 프로젝트에 대해 논의할 준비가 되어 있습니다. +86 135 5493 3315 또는 다음 주소로 이메일을 보내주세요. [email protected]

다양한 산업 분야와 협력

프로토타입 제작부터 생산까지, GHLLD는 우수한 품질과 안정적인 기능을 제공하기 위해 최선을 다하고 있습니다.. 당사의 광범위한 생산 등급 금속 및 플라스틱 소재, 고도로 발전된 주문형 제조 기술과 결합, 여러 산업 분야에 걸쳐 고품질 제품을 제공할 수 있습니다..

응용 프로그램 및 장점

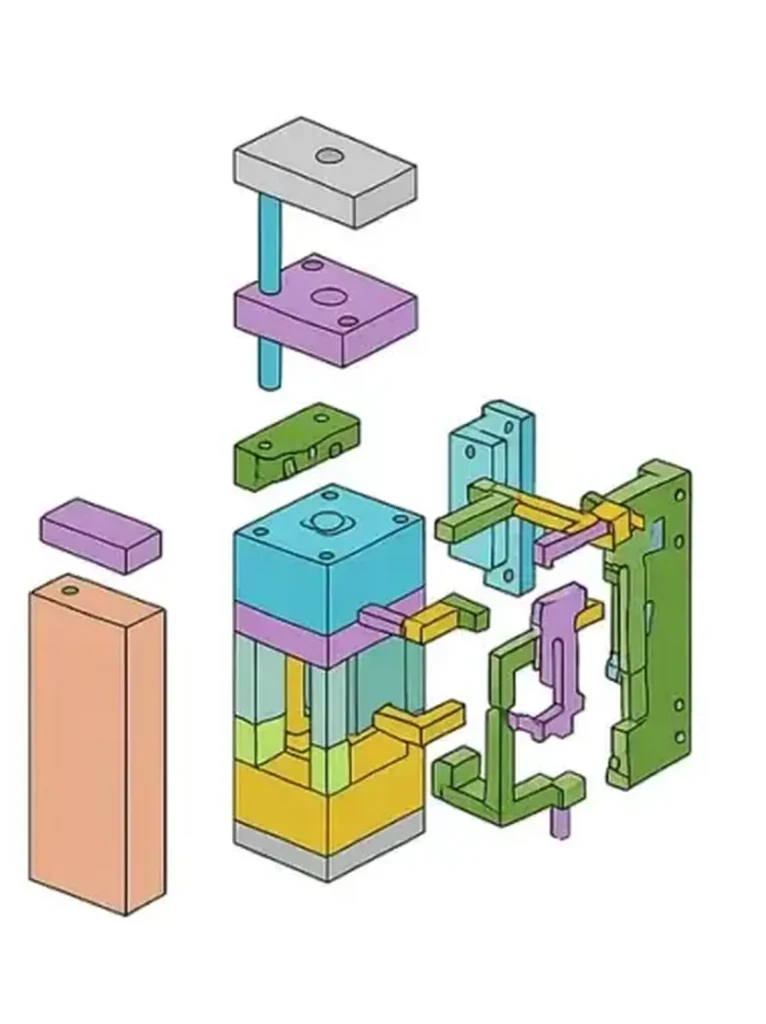

사출성형의

- 신속한 프로토타이핑

저비용 툴링을 통해 빠른 사출 성형이 가능합니다. 10 저렴한 가격으로 영업일 기준.

- 생산 부품

사출 성형. 소량 생산 모두에 이상적 (250 단위) 그리고 대량 생산 (~ 위에 1,000,000 단위), 사출 성형은 동일한 재료를 사용한 CNC 가공이나 3D 프린팅에 비해 플라스틱 부품에 탁월한 성능을 제공합니다.. 올바른 수지를 선택함으로써, 광범위한 특성과 용매 호환성을 달성할 수 있습니다.. 금형은 높은 정밀도와 엄격한 공차로 CNC 가공됩니다., 복잡한 세부 사항을 지닌 수천 개의 동일한 부품을 생산할 수 있음.

- 산업 및 인증 범위

우리는 ISO 9001, AS9100, IS0 13485, UL을 제공합니다., 이타르, 그리고 나도 7 그리고 8 의료용 클린룸 성형.

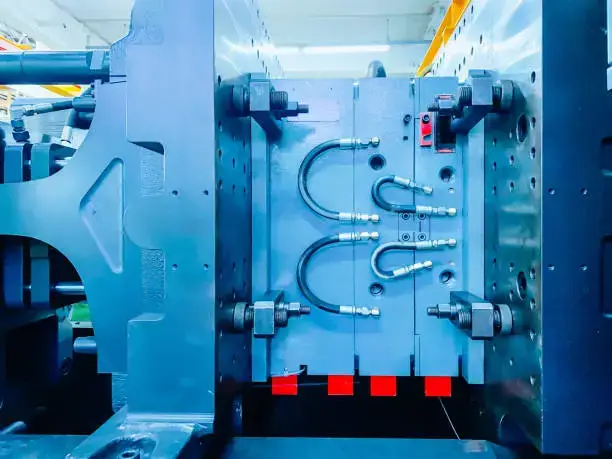

Our Injection Molding Service Processes

From quotation to final production, acknowledge the seamless order process at GHXLD. Our qualified team ensures you get your plastic molded parts within the provided lead times.

Request Instant Quote

DFM Report

Mold Design & MoldFlow

Mold Tooling Production

T1 Sample Inspection

Low Volume Production

Strict Inspection

Delivery

OUR PROJECTS

News & Media Center

Dedicated To Manufacturing Excellence