The world of plastic manufacturing is always changing. Injection molding is now a key method for making thermoplastics. This guide is for both new and experienced professionals in the field.

Understanding the Basics of Injection Molding

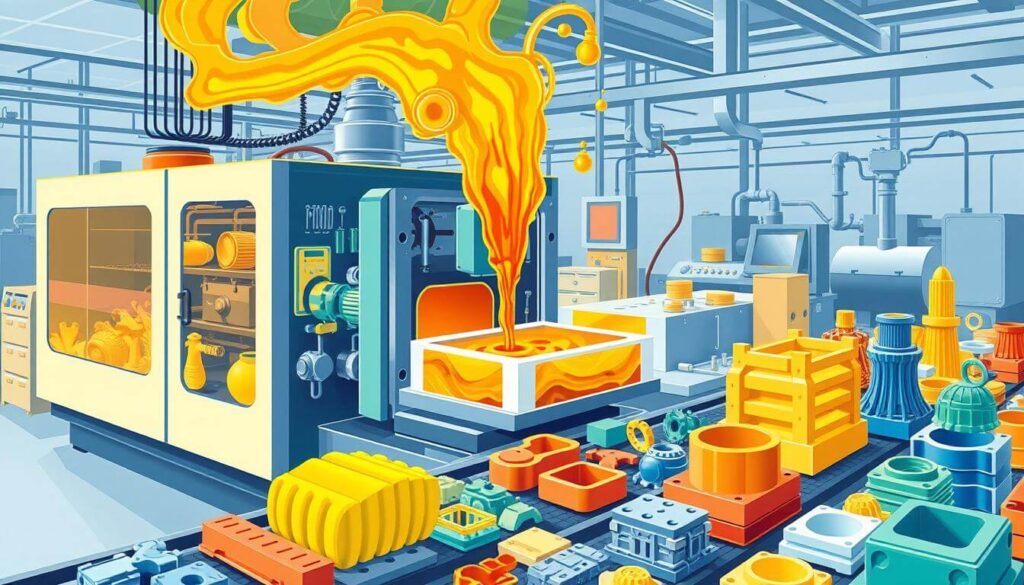

Injection molding is a key method for making many plastic items. It’s used for everything from car parts to kitchenware. The process involves melting plastic and pouring it into a mold. Once it cools, it takes the shape of the mold.

Key Components of Injection Molding Machines

Injection molding machines have important parts. Te injection unit melts and injects the plastic. Te clamping unit keeps the mold steady. Te mold is the shape of the final product, and the hopper feeds the plastic into the machine.

Types of Materials Used in Molding

- Thermoplastics: These can be melted and molded over and over. Examples include polypropylene and polyethylene.

- Thermosets: These harden permanently when molded. They can’t be melted again.

- Elastomers: These are flexible and rubber-like. They’re great for items that need to be soft and elastic.

Essential Parameters and Variables

Getting good results from injection molding depends on controlling a few key things. These include pēhanga, pāmahana, me cooling time. Adjusting these carefully helps make parts that are perfect and without flaws.

| Parameter | Description | Importance |

|---|---|---|

| Pressure | The force applied to the molten material during injection | Affects part density, dimensional accuracy, and surface finish |

| Temperature | The heat applied to melt and maintain the material’s fluidity | Impacts material properties, flow, and cycle times |

| Cooling Time | The duration the part spends in the mold to solidify | Determines part stability, dimensional stability, and cycle efficiency |

The Complete Injection Molding Process

The injection molding process is complex but efficient for making plastic products. It involves several important steps that work together to create quality parts. Let’s look at each stage and how they help the process.

The first step is mold clamping. Here, the mold’s two halves are locked together to handle the high pēhanga of injection. Then, the molten plastic material is injected into the mold, filling it accurately.

Panuku, the mold cools down. This lets the plastic solidify and shape up as desired. Te cooling is watched closely to keep the part strong and precise.

When cooling ends, the mold opens, and the part is ejected. This step is key to safely take out the part without damage.

The last step is plasticizing. Here, the machine gets ready the next batch of material. It melts, mixes, and blends the raw material for the next shot.

The cycle time is important. Or the time from clamp close to when part is released. The idea being that reducing this time leads to quicker production and lower cost.

Familiarity with the process of injection molding is essential for creating parts that are of good quality. With its steps, manufacturers can learn how to do their jobs better and to compete.

“Effective management of the injection molding process is the key to unlocking the full potential of this versatile manufacturing technique.”

Common Defects and Troubleshooting Solutions

In injection molding, even small flaws can ruin the product’s quality. Various defects can happen during making. But, with careful eyes and the right fixes, these problems can be solved.

Visual Quality Issues and Fixes

Sink marks are common, where material shrinks unevenly, making a dent. Changing the cooling time, mold pāmahana, or gate size can fix this. Flash, where extra material forms unwanted fins, can be lessened by adjusting clamping force and shot size.

Problems in Structure and Solutions

As for warping: warping occurs when parts warp from incorrect cooling or a poor mold design. Usually, this fixes by fixing in cooling system or mold shape and sometimes mould material. If you are getting “Short shots” i.e the mould is not fully filled due to under moulding you can increase ejection speed or volume to fill those.

Defects related to Processes

Problems seen in Injection molding like burn marks and flow lines. If the temperature is wrong which can overheat which can result in burn marks, you will need adjust your barrel temp/screw speed/or pressure. Improving Mold Design, Gate Position and Injection settings can minimize the flow lines.

The solution to on-chassis defects is to discover and solve these problems thus maintaining the brakes high. So they can hit their customers with the quality products.

| Defect | Pūtake | Whakamāramatanga |

|---|---|---|

| Sink marks | Uneven material shrinkage | Adjust cooling time, mold temperature, or gate size |

| Flash | Excess material seeping into mold parting line | Optimize clamping force and shot size |

| Warpage | Uneven cooling or improper mold design | Adjust cooling system, mold geometry, or material selection |

| Short shots | Insufficient injection pressure or shot size | Increase injection speed and volume |

| Burn marks | Overheating of the material | Adjust barrel temperature, screw speed, or injection pressure |

| Flow lines | Improper mold design, gate location, or injection parameters | Optimize mold design, gate location, and injection parameters |

Preventive Maintenance Best Practices

Preventive Maintenance is big in the injection molding world always. It will helpyou Maintain both your machines and molds for a long time. Doing maintenance early, reduces the machine downtime and mold maintenance issues. That drives up your throughput.

So, part and lubrication are an important aspect of maintenance. “Ensures smooth operation of different parts like bearings gears. This reduces wear and tear, saving you money on repairs.

Detergents are just as important. Cleans off grime and other damaging matter from your products. If you maintain the equipment, then you can quickly notice issues.

Equally important are scheduled inspections. They make sure you catch and fix the problems early. By this method you can prevent from big problems as well as iits help to run your equipment longer.

Your equipment will be more dependable, you save money with a proper PM. This results in higher productivity as well.

“Preventive maintenance is the bedrock of a successful injection molding operation. By proactively addressing maintenance needs, you can minimize downtime, extend equipment lifespan, and optimize production efficiency.”

Optimizing Production Efficiency and Quality

In the world of injection molding, making production efficient and controlling quality is key. Using lean manufacturing helps manufacturers work better, cut down on waste, and improve quality.

Cycle Time Optimization

Improving cycle time is a big part of being efficient. By using statistical process control me automation, manufacturers can make their processes smoother. This cuts down on downtime and makes things faster.

This not only makes production more efficient but also means they can meet customer needs quicker.

Material Selection and Management

Choosing the right materials and managing them well is vital for quality and reducing waste. By picking materials based on their properties, manufacturers can meet their goals. Good material management practices also help reduce waste.

Quality Control Measures

Keeping quality high is crucial in injection molding. Using quality control measures like strict inspections and analysis helps catch problems early. This way, manufacturers can make sure their products are top-notch and work efficiently.

| Optimization Strategies | Key Benefits |

|---|---|

| Cycle Time Optimization | Increased production efficiency, faster turnaround, and improved responsiveness to customer demands. |

| Material Selection and Management | Consistent quality, reduced scrap, and enhanced lean manufacturing efforts. |

| Quality Control Measures | Improved product quality, early detection and resolution of defects, and overall production optimization. |

By using these strategies, injection molding companies can improve a lot. They can make their production more efficient, ensure quality, and stay competitive.

Safety Protocols and Environmental Considerations

Keeping workers safe and protecting the environment are key in the injection molding world. Workers must wear personal protective equipment (PPE) like safety goggles, gloves, and protective clothes. This helps prevent injuries during handling materials and operating machines.

Safe handling of materials is vital to avoid accidents. Using the right tools and equipment for lifting and moving heavy molds and parts is important. Also, following safe steps for loading raw materials and unloading finished parts is crucial. These steps help keep the workplace safe for everyone.

Environmental care is also a big deal. Injection molding should recycle plastic waste whenever it can. This helps lessen the industry’s impact on the environment. Using energy wisely, like setting machines to use less power and using green energy, also makes production more eco-friendly.

Key Safety and Environmental Practices

- Mandatory use of personal protective equipment (PPE) for all employees

- Tika material handling techniques to prevent injuries

- Responsible recycling and disposal of plastic waste

- Optimization of energy consumption through efficient machine settings

- Exploration of renewable energy sources to power injection molding operations

| Safety Measure | Environmental Impact |

|---|---|

| Use of PPE | Reduced risk of workplace injuries |

| Tika material handling | Improved ergonomics and reduced strain |

| Plastic waste recycling | Decreased landfill and greenhouse gas emissions |

| Energy-efficient practices | Lower energy consumption and carbon footprint |

By focusing on safety and being green, injection molding places can keep workers safe, cut down on environmental harm, and help make the industry more sustainable.

“Occupational safety and environmental responsibility are not dire moral requirements but, strategic imperatives for the continued success — long term if you started YesterInjection Molding is.”

注重安全和绿色, 注塑场所可以保证工人的安全, 减少环境危害, 并帮助该行业更具可持续性.