Ko te hanga werohanga e rua-tae he huarahi ki te whakakotahi i nga rawa rereke e rua, i nga tae ranei ki tetahi waahanga kirihou. This method makes it possible to create complex, multi-functional items. These items look great and work well.

By using different materials, makers can make plastic parts that look good and work well. This is why two-color injection molding is important in today’s product design and engineering.

Principles and Process Flow

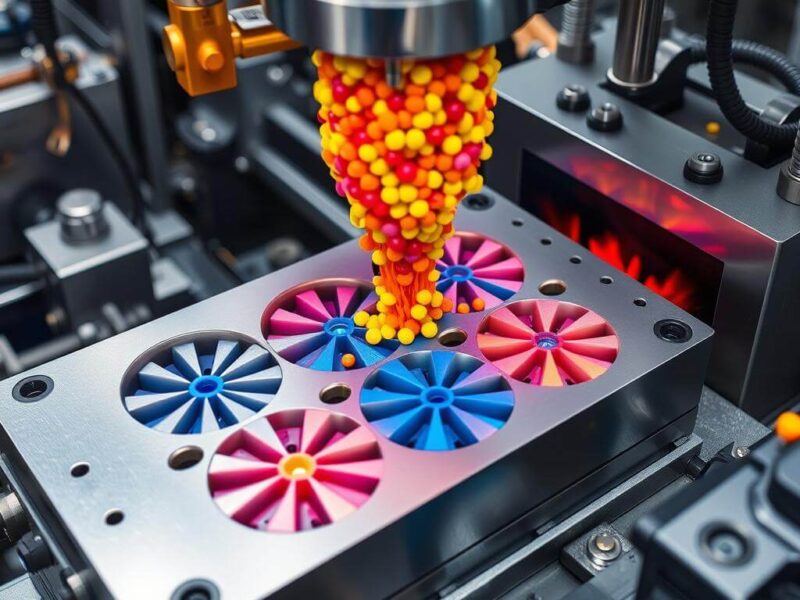

The two-color molding process uses two different melted plastics at the same time. This makes parts with different colors, textures, or materials. First, one plastic is injected, then the second one is added, either by another unit or by moving the mold.

Key Components of Multi-color Molding Systems

- Dual-barrel injection molding machine or a machine with multiple injection units

- Specialized mold design with complex cavities and intricate core/cavity configurations

- Precise material selection me polymer compatibility to ensure strong adhesion between the two materials

- Advanced process control and monitoring systems to manage temperatures, pressures, and timing

Material Compatibility Requirements

Choosing the right materials is key for two-color molding. The plastics must stick well together. Things like melt flow rates, shrinkage rates, me thermal expansion coefficients need to match. Sometimes, special layers are needed to help the plastics bond better.

“Two-color injection molding is a game-changer in the world of product design, opening up a realm of creative possibilities for manufacturers.”

Benefits and Applications of Two-color Molding

Two-color injection molding is a cost-effective method used in many industries. It makes products look better and work better. This technique saves money and boosts the quality of the final product.

This method helps reduce assembly by combining parts into one. It saves time and money, making it a smart choice for businesses. It also lets designers use different materials, making products more functional and interesting.

In the car world, two-color molding is great for making fancy parts like dashboards and trim. It lets makers mix colors and textures, making cars look better.

For gadgets, two-color molding makes them look and feel better. It’s used in phones and computers, making them sleek and easy to use. This technology has changed how these items are made.

“Two-color injection molding has been a game-changer for our industry, allowing us to produce parts that are not only cost-effective but also visually stunning and highly functional.”

– Jane Doe, Director of Manufacturing, XYZ Electronics

As people want new and unique products, two-color molding is becoming more popular. It’s a smart choice for makers who want to save money but still make high-quality items.

Different Types of Multi-material Injection Methods

In the world of co-injection molding me multi-shot molding, many techniques are used to make complex, multi-colored parts. These include the simultaneous injection process, the sequential injection technique, and the core back molding method. Each method has its own benefits and things to consider.

Simultaneous Injection Process

The simultaneous injection process injects two or more materials into the mold at once. It’s great for making parts with detailed color patterns. But, it needs careful control over material mixing and processing to work well.

Sequential Injection Technique

The sequential injection technique injects materials one after the other. It’s often used for parts with clear, separate colors. This method is easier to manage and offers more flexibility in material choice.

Core Back Molding Method

The core back molding method uses a retractable core to make complex multi-material parts. First, one material is injected, then the core is pulled back for the second material. It’s perfect for parts with complex shapes and clear material boundaries.

Each injection method has its own advantages and limitations. They are best for different needs and products. Manufacturers should pick the right method for co-injection molding, multi-shot molding, me rotary platen technology to get the desired results.

| Injection Method | Key Characteristics | Suitable Applications |

|---|---|---|

| Simultaneous Injection | Injecting two or more materials at the same time | Parts with complex color patterns, seamless material integration |

| Sequential Injection | Injecting materials one after the other | Two-color or multi-material parts with distinct component separation |

| Core Back Molding | Utilizing a retractable core to create intricate multi-material parts | Complex geometries with distinct material interfaces |

Design Considerations for Two-color Parts

Creating successful two-color injection molded parts needs careful thought. You must consider part geometry, material choice, and where to place gates and vents. Each part is key to the product’s success.

The part’s shape is crucial. A smooth, symmetrical design helps the materials blend well. It ensures even distribution and reduces issues at the material join.

Choosing the right materials is also vital. They must bond well and handle the molding process stress. You need to look at thermal expansion, shrinkage rates, and viscosity to ensure a good mix.

Where you place gates is also important. They should help fill the mold evenly and avoid defects. Mold flow analysis helps find the best gate spots for even material flow.

Venting is another critical factor. Good venting prevents air from getting trapped, which can cause problems. By thinking about part design, material, gates, and vents, you can make parts that look great and work well.

“Successful two-color injection molding requires a deep understanding of the interplay between part design, material selection, and mold flow dynamics.”

Common Challenges and Troubleshooting Tips

Two-color injection molding is a complex process. It can face many challenges. Knowing how to solve these problems is key to making high-quality parts efficiently.

Material Interface Issues

Ensuring a strong bond between different materials is a big concern. Delamination, where materials separate, is a major issue. To avoid this, choose materials that work well together and adjust their properties.

Timing and Temperature Control

Getting the timing and temperature right is crucial. Warping me color bleeding happen if the process isn’t controlled well. Adjusting injection speeds, mold temperatures, and cooling times can solve these problems.

Quality Control Measures

Keeping product quality consistent is a big challenge. Process optimization is vital to meet quality standards. Use quality checks like in-process inspections and statistical process control to catch and fix any issues.

By tackling these common problems and using effective solutions, manufacturers can make the most of two-color injection molding. They can create high-quality, attractive products that meet market needs.

Why Choose GHXLD for Two-Color Injection Molding?

Whakapaa mai ki a maatau i tenei ra for a quote or to learn more about our two-color molding capabilities!

推动创新和卓越。