In the competitive world of automotive manufacturing, precision, quality, and efficiency are paramount. A single mold defect can halt production lines, costing OEMs over $22,000 per hour (Deloitte Automotive Report). That’s where XLD Mould steps in as a trusted partner for high-precision automotive mold solutions. With decades of experience, cutting-edge technology, and a commitment to excellence, XLD Mould is your go-to choice for automotive mold solutions. Here’s why.

1. Technical Capabilities Built for Automotive Excellence

XLD Mould understands that the automotive industry demands zero-tolerance perfection. We specialize in high-precision automotive injection molds that meet stringent global standards, reducing the total cost of ownership by 18-25%. Let’s take a closer look at how we achieve excellence:

1.1 Precision Engineering

Tolerance Control: At XLD Mould, we ensure precision with tolerances as tight as ±0.005mm for critical components such as sensor housings and connectors.

Materials Expertise: We select the best materials based on your project’s requirements:

- Glass-Filled Nylon: For engine covers, withstands 180°C continuous use.

- PBT + 30% GF: Ideal for EV battery housings, offering UL94 V-0 flame resistance.

- LSR (Liquid Silicone Rubber): Perfect for seals and gaskets, offering -40°C to 200°C flexibility.

For more details, check out our Automotive Material Selection Guide.

1.2 Industry 4.0-Driven Production

Smart Molds: Our IoT-enabled molds allow real-time monitoring of pressure and temperature, predicting maintenance needs before they impact production.

AI-Powered Design: Our Mold Flow Analysis reduces trial iterations by 40%, speeding up the prototyping and production phases. For instance, in a EV charger port project, our AI-driven designs saved both time and costs.

2. Proven Track Record of Solving Complex Automotive Challenges

Kei Maeneene Xld, we don’t just design and manufacture molds – we solve problems. Here’s a prime example:

Case Study: Solving a Tier-1 Supplier’s Headlight Lens Crisis

Client Profile: Automotive Lighting Supplier

Challenge: 12% warpage in PC/PMMA hybrid lenses due to uneven cooling.

XLD’s Solution:

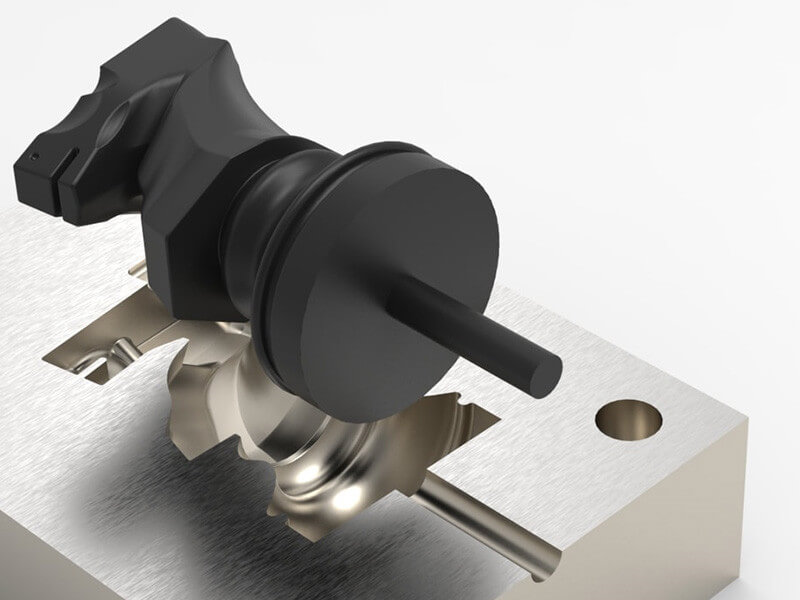

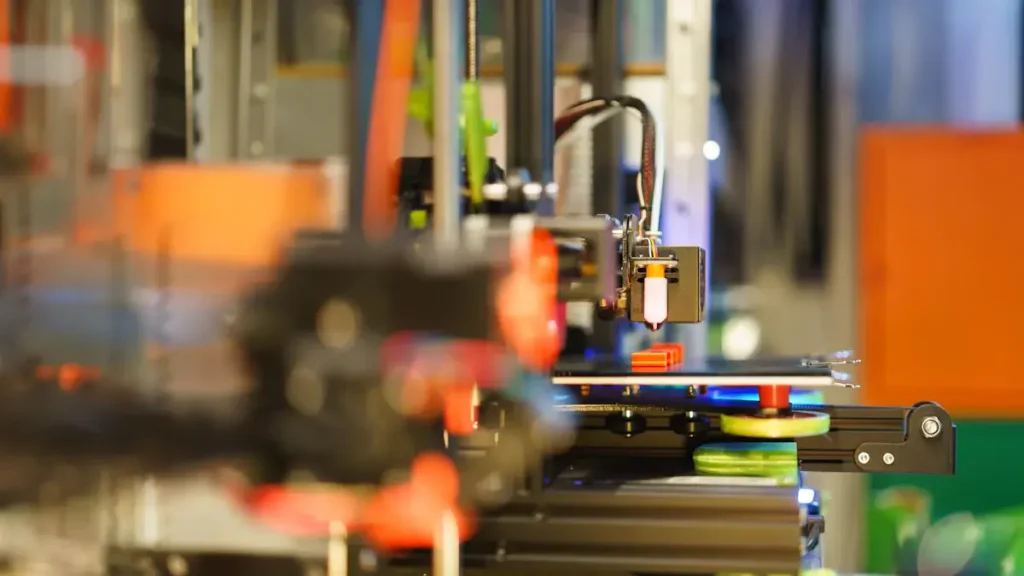

- Conformal Cooling Channels: 3D-printed mold inserts reduced temperature variance to ±2°C.

- Vacuum Venting System: Eliminated gas traps causing surface defects.

- Zero-Draft Angle Design: Enabled seamless demolding for complex optics.

Results:

- Defect Rate: Reduced from 12% ki 0.3%

- Cycle Time: Reduced from 55s to 38s

- ROI: Saved $480,000/year in scrap and downtime.

Download the full case study to learn more.

3. Certifications & Compliance You Can Trust

Maeneene Xld adheres to the highest industry standards, ensuring your molds meet or exceed all regulatory requirements:

- IATF 16949: Full compliance for automotive quality management.

- Iso 14001: Sustainable production with 98% material utilization.

- PPAP Documentation: Accelerated OEM approval processes.

You can verify our credentials in our Certifications Hub.

4. Cost Optimization Strategies

We understand that cost efficiency is crucial for your bottom line. XLD Mould offers various strategies to optimize both design and production costs:

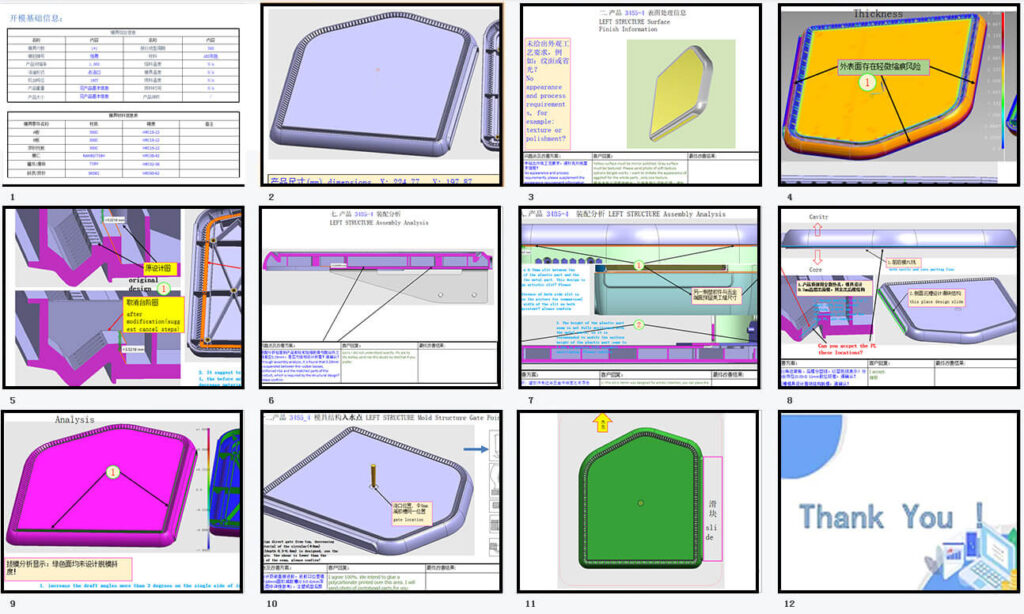

4.1 Design-for-Manufacturing (DFM) Ratonga

Our engineers provide free DFM analysis to review your CAD files and:

- Eliminate undercuts requiring complex sliders.

- Optimize wall thickness for 15-20% material savings. For example, we redesigned a mirror housing mold, reducing tooling costs by $28,000.

4.2 Flexible Production Models

We offer flexible production models tailored to your needs:

- Prototype Molds: Delivered in 15-20 days for concept validation.

- High-Cavity Molds: Delivered in 30-45 days, ideal for mass production (100K+/mo).

- Maintenance Packages: 24/7 support to maximize mold lifespan.

Get an Instant Quote now.

5. Why Global Automotive Leaders Choose XLD Mould

XLD Mould has earned the trust of top automotive companies worldwide, delivering over 200 automotive projects between 2018-2023. We offer end-to-end support from design through post-mold services such as assembly and packaging. Tāpiritanga, our global logistics network ensures 15-day door-to-door delivery to EU/US/Mexico hubs.

Client Testimonial:

“XLD’s team resolved our EV battery tray warping issue in 72 hours – their technical response is unmatched.” – John Muller, VP of Procurement, [Automotive OEM]

Wāhanga whakamutunga: Accelerate Your Automotive Success with XLD Mould

At XLD Mould, we provide more than just molds – we deliver precision, speed, and cost efficiency that accelerate your automotive manufacturing process. Our cutting-edge technology, expertise in materials, and customized solutions make us the trusted partner you need for your automotive molding needs.

Next Steps:

- Explore our Automotive Portfolio.

- Speak to an Expert for a free consultation.

- Download our White Paper: 5 Trends Shaping Automotive Precision Molding.

With extensive experience in automotive, hauora, and consumer electronics industries, we provide tailored mold solutions that meet the highest precision standards. Our commitment to innovation, quality, and customer satisfaction ensures that you receive the best-in-class injection molding services.