O tempo do ciclo de moldagem por injeção é um dos fatores mais críticos que influenciam a eficiência da fabricação, custos de produção, e lucratividade geral. Reduzir o tempo do ciclo, mantendo a qualidade da peça, pode melhorar significativamente a produção de produção e reduzir as despesas operacionais. Este artigo explora os principais fatores que afetam o tempo do ciclo de moldagem por injeção e fornece estratégias acionáveis para otimizar o processo.

1. Entendendo o tempo do ciclo de moldagem por injeção

O tempo do ciclo de moldagem por injeção é a duração total necessária para produzir uma única peça moldada, incluindo os seguintes estágios:

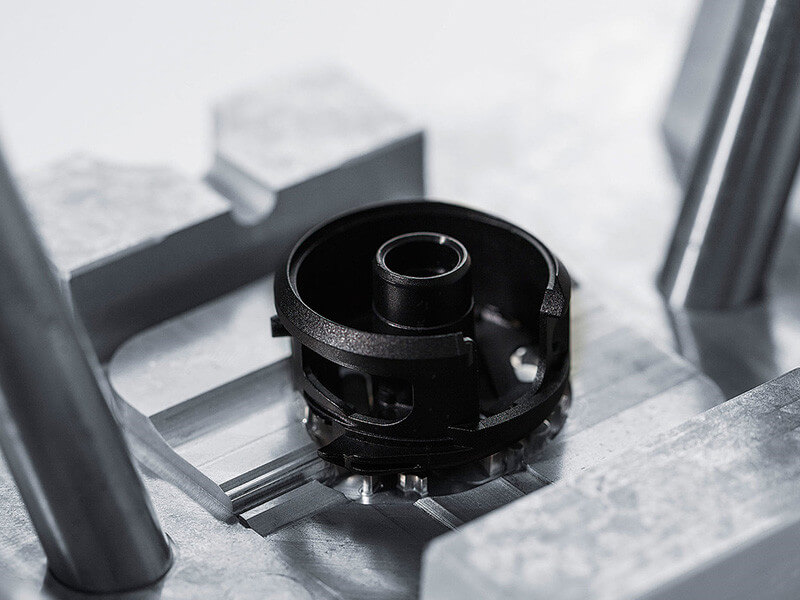

- Fase de injeção: O plástico fundido é injetado na cavidade do molde.

- Packing and Holding Phase: The mold remains under pressure to eliminate voids and ensure part integrity.

- Cooling Phase: The material solidifies within the mold.

- Ejection Phase: The part is released from the mold.

- Mold Resetting Phase: The mold closes and prepares for the next cycle.

Optimizing each phase can significantly reduce cycle time while ensuring quality and process stability.

2. Key Strategies to Reduce Injection Molding Cycle Time

2.1 Optimize Injection Speed and Pressure

- Adjust the injection speed to balance material flow without causing defects such as flash or short shots.

- Reduce excessive pressure while maintaining adequate material distribution.

- Implement scientific molding techniques to fine-tune process parameters.

2.2 Improve Cooling System Efficiency

Cooling time typically accounts for 60-70% of the total cycle time, making it a key area for optimization.

- Use conformal cooling channels to ensure uniform temperature distribution and faster heat dissipation.

- Implement high-thermal-conductivity mold materials, such as beryllium copper, to enhance cooling performance.

- Optimize coolant flow rate and temperature to maintain consistent part cooling.

- Apply mold temperature controllers (MTCs) to regulate heat balance and minimize temperature fluctuations.

2.3 Optimize Mold Design for Faster Processing

- Use multi-cavity molds to produce multiple parts per cycle, reducing total cycle time per part.

- Design the mold with smooth flow paths and proper venting to minimize material resistance and air traps.

- Aplique um sistema de corredor quente para eliminar corredores frios, Reduzindo o desperdício de material e o tempo de injeção.

- Implementar um sistema de ejeção eficiente, como placas de ar ou stripper, Para acelerar a remoção de peças.

2.4 Reduza o tempo de fixação e ejeção

- Otimize a velocidade de abertura e fechamento do molde para minimizar atrasos.

- Use Grampos de alternância acionados por servo Para aplicação de força de fixação mais rápida e precisa.

- Garanta a lubrificação e manutenção adequadas para evitar atrito desnecessário e atrasos.

- Implement robotic automation for quick and consistent part removal, reducing manual handling time.

2.5 Use Advanced Materials and Additives

- Select materials with lower viscosity to enhance flow characteristics and reduce filling time.

- Utilize specialized additives that promote faster cooling and improved demolding properties.

- Consider preheated resin materials to shorten the melting phase and improve cycle consistency.

2.6 Implement Automation and Real-Time Monitoring

- Use real-time process monitoring sensors to track cycle time and identify inefficiencies.

- Implement automated robotic systems for part removal and secondary operations, reducing idle time.

- Utilize AI-driven process control to adjust settings dynamically for optimal efficiency.

2.7 Optimize Process Parameters with Scientific Molding

- Perform DOE (Design of Experiments) to identify the most efficient cycle settings.

- Utilize process simulation software (e.g., Moldflow) to predict and optimize cycle times.

- Maintain consistent melt temperature to prevent variations that could lead to extended cycle durations.

3. The Benefits of Cycle Time Reduction

By successfully reducing injection molding cycle time, manufacturers can achieve several benefits:

- Increased Production Efficiency: Higher output in less time leads to greater profitability.

- Lower Manufacturing Costs: Reduced cycle time translates to lower energy and labor costs per part.

- Improved Part Quality: Optimized cooling and processing conditions reduce defects and enhance consistency.

- Sustainability and Energy Savings: Faster cycles mean lower power consumption and material waste.

Conclusion

Reducing injection molding cycle time requires a strategic approach involving material selection, process optimization, mold design improvements, and automation. By implementing these techniques, manufacturers can achieve higher productivity, reduced costs, and improved product quality. For expert solutions in cycle time optimization, Molde xld Fornece experiência avançada de moldagem por injeção para ajudar as empresas a maximizar a eficiência e a lucratividade.