In today’s manufacturing world, picking between thermoforming and injection molding is key. These methods are used to make high-quality plastic parts. Each has its own benefits and things to think about, based on your project needs and budget.

This article will go into the details of these processes. We’ll help you decide which one fits your needs best. We’ll look at the main differences, costs, materials, and how they affect production volume and speed. By the end, you’ll know which method is best for your plastic projects.

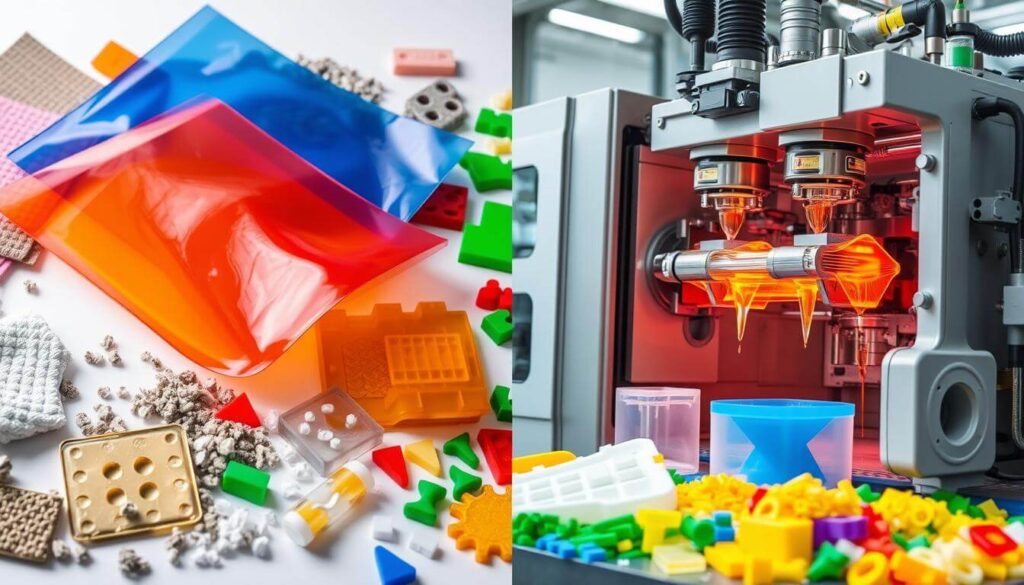

Injection Molding vs Thermoforming

Thermoforming vs. injection molding: Two dominant plastic part manufacturers processes with unique advantages and considerations. live] If you enjoyed this article, please consider sharing it, and are not already a subscriber, please subscribe today so we can continue to bring you quality, independent news and information. Which you choose depends on things like:

- Production Volume

- Design Flexibility

- Time-to-Market Requirements

By carefully assessing project-specific requirements and conducting a cost-efficiency analysis, businesses can identify the best-suited plastic manufacturing solution. Keeping abreast of industry trends and technological improvements can also play a role in the decision-making process.

Understanding the Basics of Both Manufacturing Processes

Manufacturers often face a choice between thermoforming and injection molding when producing plastic products. Each method has its own strengths and is better suited for specific types of products. Here’s a quick overview of both:

What is Thermoforming?

Thermoforming means heating sheets of plastic until they are pliable, and molding them into the shape of the product. All these methods are especially good for big, cross-sectional components, giving great design freedom. It is commonly used for packaging, ชิ้นส่วนยานยนต์, and other large, low- to medium-complexity products.

What is Injection Molding?

In contrast, injection molding utilizes molten plastic, which is injected into the molds under high pressure. This is an ideal process for manufacturing small to medium parts requiring high precision and repeatability. Injection molded components are typically used in applications requiring complex geometries and tight tolerances, such as in the manufacture of medical components, consumer products, and automotive components.

Key Differences in Process Methods

Thermoforming and injection molding both aim to shape plastic into parts, but they do it differently. Thermoforming uses heated plastic sheets, while injection molding injects molten plastic into molds. These different approaches lead to unique benefits and limitations for each method.

| Characteristic | Thermoforming | การฉีดขึ้นรูป |

|---|---|---|

| Raw Material | Heat-formed plastic sheets | Molten plastic resin |

| Shaping Process | Heating and forming plastic sheets into molds | Injecting molten plastic into mold cavities |

| Part Complexity | Suitable for large, complex parts | Suitable for small to medium-sized, intricate parts |

| Production Techniques | Vacuum forming, pressure forming, mechanical forming | Mold filling, packing, cooling, ejection |

Cost Considerations: Investment and Production Expenses

When making decisions about manufacturing, money matters a lot. Both thermoforming and injection molding have their own costs. These costs include the initial investment and what it costs to keep producing.

The tooling costs for thermoforming are usually lower than for injection molding. Thermoforming molds are simpler and cheaper to make. This makes it easier for businesses to get started. On the other hand, injection molding molds are more complex and expensive. This can make the initial equipment investment higher.

But, the production volume can change these costs. Injection molding is better for making lots of parts because the high tooling costs spread out over many parts. Thermoforming is better for making fewer parts because the lower tooling costs save money.

| Cost Factors | Thermoforming | การฉีดขึ้นรูป |

|---|---|---|

| Tooling Costs | Generally lower | Typically higher |

| Equipment Investment | More accessible | Often costlier |

| Production Volume | Suitable for lower volumes | More cost-effective for higher volumes |

| Material Expenses | Typically lower | May be higher due to waste |

There are also ongoing material expenses and energy use to think about. Thermoforming often uses less material and has less waste. Injection molding might use more material and waste more.

In the end, choosing between thermoforming and injection molding depends on the project, how many parts you need, and your budget. You need to weigh these factors carefully to find the best way to make your product.

Material Selection and Compatibility

Choosing the right materials is key in manufacturing. Thermoforming and injection molding use different thermoplastics. Knowing these options helps decide between the two.

Compatible Materials for Thermoforming

Thermoforming works well with many thermoplastics. These include polystyrene (ป.ล), polyethylene (วิชาพลศึกษา), polypropylene (พีพี), polyvinyl chloride (PVC), and acrylonitrile butadiene styrene (ABS). These thermoplastics are great for their material properties. They are strong, clear, and easy to shape, making them perfect for many uses.

Suitable Materials for Injection Molding

Injection molding can use even more thermoplastics. It includes the ones mentioned before and others like polycarbonate (พีซี), polyamide (PA), and thermoplastic elastomers (TPEs). These are picked for their special polymer selection และ material properties. They meet a wide range of product needs.

Material Waste Comparison

Injection molding makes less waste than thermoforming. It’s because the material is injected precisely, cutting down on scraps. Thermoforming, however, can lead to more waste. This is because the material is stretched and formed, leaving more to be thrown away.

“The choice between thermoforming and injection molding should be driven by the specific requirements of the product, including the desired material properties, production volume, และ recycling potential.”

Production Volume and Scalability Factors

The choice between thermoforming and injection molding comes down to production volume and scalability. These factors are important in choosing the right method for your needs. These choices matter, whether you need small batches, mass production or something in between.

Thermoforming is excellent for the types of product customizations which are small scale, as well as for low-to-medium volume manufacturing. It has low tool costs and short setup times. This means it is flexible and best-suited for niche markets or changing demands.

Injection molding is best for high-volume, mass production. It requires a bigger upfront investment in molds but is automated and fast. This is ideal for making lots of the same product with consistent batch sizes.

| Factors | Thermoforming | การฉีดขึ้นรูป |

|---|---|---|

| Batch Sizes | Small to medium | Large |

| Manufacturing Flexibility | High | Moderate |

| Lead Times | Shorter | Longer |

| Tooling Costs | Lower | Higher |

When looking at production volume and scalability, think about your business needs and growth. Thermoforming might be best for startups or small businesses. Injection molding is better for big companies needing to make lots of the same thing.

“The ability to scale production is a key consideration when choosing between thermoforming and injection molding. Businesses must carefully assess their current and future needs to determine the most suitable manufacturing process.”

Design Capabilities and Limitations

The choice between thermoforming และ injection molding impacts your product’s design, including shape, surface finish, and complexity. Here’s a comparison of their design capabilities and limitations:

Achievable Geometries

- Thermoforming produces complicated three-dimensional shapes, including parts with undercuts and deep draws. It’s best for complex designs and dimensional precision.

- Injecting Molding is more suited for simpler, more uniform shapes. Though capable of some complexity, it struggles with producing fine details and surface textures.

Surface Finish Options

- Thermoforming allows a variety of surface finishes, such as glossy, textured, and custom patterns, making it suited for products that need to focus on aesthetics and branding.

- การฉีดขึ้นรูป provides a smoother, more uniform finish, but has fewer surface texture options than thermoforming, making it more suitable for clean, consistent looks.

Part Complexity

- Thermoforming is highly flexible for producing complex parts with intricate features, such as undercuts and deep draws.

- การฉีดขึ้นรูป is better suited for simpler, more uniform parts, with less flexibility for complex designs due to the need for expensive and time-consuming tooling adjustments.

| Thermoforming | การฉีดขึ้นรูป |

|---|---|

| Greater design flexibility | Better suited for simpler geometries |

| Excels at intricate, 3D shapes and contoured surfaces | Limited range of surface textures และ intricate details |

| Wide variety of surface finish options | Typically yields a smoother surface finish |

| Well-suited for complex geometries and การปรับแต่ง | Better for parts with simpler designs and uniform wall thicknesses |

Quality and Consistency in Manufacturing

Choosing the right manufacturing process is key. It’s all about the quality and consistency of the product. Thermoforming and injection molding have their own strengths. Knowing these can help you decide better.

Injection molding stands out for its uniformity. It’s a highly automated process with tight control. This means parts are very accurate and have a consistent finish. It also leads to fewer defects and better quality control.

| Metric | Thermoforming | การฉีดขึ้นรูป |

|---|---|---|

| Dimensional Accuracy | ±0.5% to ±3% | ±0.005″ to ±0.020″ |

| Surface Finish | Dependent on mold surface | Highly consistent, mirror-like finish |

| Defect Rates | Moderate, can be affected by material and process variations | Low, due to high process control and repeatability |

Thermoforming, on the other hand, might have a bit more variation. This is because it depends on material, mold, and heating/cooling. But, new tech has made thermoforming better at quality control และ process repeatability.

So, whether to choose thermoforming or injection molding depends on your needs. Both are reliable. But, think about what you need for uniformity, quality control, defect rates, และ process repeatability. This will help you pick the best option.

Time to Market and Production Speed: Injection Molding vs. Thermoforming

Both injection molding และ thermoforming offer fast production methods, but they differ in terms of tooling, production cycle times, and setup flexibility. Understanding these differences can help businesses better plan for their project timelines, especially when considering tight deadlines or rapidly changing demands.

Tooling Lead Times

Injection Molding demanding more complex molds, taking more time to design and build the molds. This can push back the production start and is therefore not ideal for short time-line projects.

Thermoforming, however, uses simpler (and less expensive) molds and can start production faster. Because the small action can be performed faster and require very little effort, this will be an advantage for companies with soon-deadlines need, then when the market are changing or just to meet urgent needs.

Production Cycle Times

การฉีดขึ้นรูป, on the other hand, has shorter cycle times (once tooling is created) and is more effective for large-scale production runs or high-demand projects. It can manufacture thousands and thousands of quick products.

Thermoforming is more versatile about small batches. It may not be as fast as injection molding for high-volume production runs, but can be swiftly adapted to changes in product design or production needs, making it well-suited to short runs or prototypes.

Requirements for Setup and Changeover

Injection Molding takes a bit longer for setup. Careful adjustments and setup changes for each new product run are time-consuming. This makes it suited to high volumes of the same product, but not suited to frequent changeovers.

Thermoforming is easier to set up and change from one product to another. Its well-suited for manufacturers that need to quickly adapt their product designs or that have task scheduling needs across a variety of products with frequent production changes.

推动创新和卓越。