What Is Plastic Injection Molding?

Plastic Injection Molding is a cost-effective and efficient manufacturing process used to produce high-volume custom plastic parts with precision and complexity. It involves injecting molten plastic into a mold, where it cools and solidifies to form the desired shape, making it ideal for mass production where large quantities of identical parts are needed.

The key advantage of injection molding is its scalability: after covering initial setup costs, the cost per unit drops significantly, offering manufacturers a cost-efficient solution for high-volume production. This process is widely used across industries such as automotive, electronics, medical, and consumer goods, thanks to its ability to deliver high-quality, durable parts quickly and economically.

How Does Plastic Injection Molding Work?

Plastic injection molding is a versatile and efficient manufacturing process used to create custom plastic parts for a wide range of industries. It is particularly valued for its ability to produce high-quality, complex components in large volumes with consistent precision. Understanding how this process works can help businesses optimize their production and achieve cost-effective results.

1. การเลือกใช้วัสดุ

The process begins with selecting the appropriate plastic resin based on the specific requirements of the product. Factors such as durability, flexibility, chemical resistance, and temperature tolerance influence the choice of material.

2. Melting and Injection

Heating: Plastic pellets or granules are fed into the machine’s hopper and heated in a barrel until they reach a molten state.

Injection: The molten plastic is injected into a custom-designed mold under high pressure. The pressure ensures the material fills every cavity of the mold, capturing the intricate details of the design.

3. Cooling and Solidification

Once the mold is filled, the plastic cools and hardens to take the shape of the mold. The cooling time depends on the size and material of the part, with precision cooling mechanisms ensuring the part retains its desired properties and shape.

4. Ejection

After solidification, the machine’s ejection system removes the finished part from the mold. The mold then closes, and the process repeats for the next cycle.

5. Post-Processing

Once ejected, the parts may undergo additional steps, such as:

- Gate Trimming:Excess material, such as flash or runners, is removed manually or with automated tools to achieve clean edges and precise dimensions.

- Deburring:Defects like burrs along parting lines are smoothed out using hand tools or automated processes like tumbling and sandblasting, ensuring a safe and polished surface.

- Ultrasonic Welding:High-frequency vibrations bond multiple parts seamlessly, eliminating the need for adhesives or fasteners while ensuring durability.

- Secondary Operations: The final part may be required to be painted, plated, heat staked, and assembled, or there may be a need for the addition of fasteners or inserts.

What Products Are Made From Plastic Injection Molding?

Injection molding can produce parts with a variety of finishes and textures, making it possible to create parts that are both functional and aesthetically pleasing.

Plastic injection molding is used in various industries due to its ability to produce high-quality, durable parts:

- ยานยนต์: Injection molding is used to produce car dashboards, interior panels, engine components, and electronic system parts. The ability to create complex shapes makes it ideal for automotive applications.

- Medical: Syringes, tubing, surgical equipment, and medical packaging are all made through plastic injection molding. Its precision and accuracy make it crucial in the medical industry, where safety and reliability are essential.

- Consumer Products: Plastic injection molding is commonly used to manufacture kitchenware, household appliances, toys, and more, offering a cost-effective solution for producing high-quality consumer goods.

- Packaging: Injection molding is widely used for creating packaging materials such as bottle caps, food containers, and jars. The process produces high-quality finishes, making it ideal for packaging applications.

- การบินและอวกาศ: Interior and exterior parts of spacecraft, including panels and connectors, are made using injection molding. The process produces lightweight, high-strength parts that can endure the extreme conditions of space travel.

- Military and Defense: Injection molding is used to manufacture components for military equipment such as weapons, communication devices, and artillery. The molded parts are durable and can withstand harsh impact forces.

- Furniture: Plastic injection molding is commonly used in the furniture industry to create plastic parts like chair and table legs, door handles, racks, and knobs, offering durability and design flexibility.

- Energy and Utilities: Components for solar panels, wind turbines, and electrical systems are produced using injection molding, providing protection against environmental factors like temperature, moisture, and chemicals.

Types of Plastic Injection Molding

Plastic injection molding offers a range of techniques to meet various manufacturing needs. Each type caters to specific applications, materials, and production goals, making this method highly versatile. Below are the most common types:

1. Standard Molding

Ideal for mass-producing consistent plastic parts, commonly used in consumer goods, ยานยนต์, and medical industries.

2. การปั้นมากเกินไป

A secondary plastic is an injection molded over a primary plastic part already in the mould. Creates a two-material part with an inner core and outer layer. Used for grips, buttons, seals, etc.

3.แทรกการปั้น

Inserts made of metal, ceramics or other non-plastic materials are placed in the mould cavity first before injection of molten plastic. Useful for electrical or mechanical parts.

4. Gas-Assisted Injection Molding:

Pressurized gas (typically nitrogen) is injected into the molten plastic to create hollow channels and cavities in the part, reducing sink marks and warpage. Used for large, hollow parts. Produces lightweight, hollow parts using gas, reducing material usage for products like automotive panels and furniture.

5.Two-Shot Molding

Two-shot molding, 2K shot molding, or dual-shot molding produces complex moldings from two materials during a single cycle. This process is beneficial when different properties are desired in different areas of the part.

6. Thin-Wall Injection Molding:

Specializes in lightweight, strong parts with minimal material use, commonly used in packaging and food containers.

Each method caters to specific applications, ensuring cost-effectiveness, ความแม่นยำ, and optimal performance across industries.

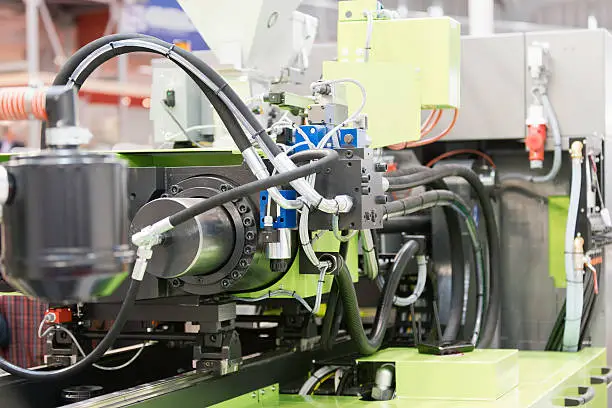

Components of Plastic Injection Molding Machine

Some of the main parts of a plastic injection molding machine include:

- Injection unit

- Clamping unit

- Mold

- Ejector system

- Control system

- Heating system

- Cooling system

Advantages of Plastic Injection Molding

- High Efficiency: Ideal for large-scale production of identical parts, reducing manufacturing time and cost.

- Low Waste: The precision of the process results in minimal material waste, contributing to its eco-friendly nature.

- Design Flexibility: Injection molding supports a range of part designs, from simple to complex, while maintaining high quality and durability.

- Consistency: Parts produced are highly consistent, ensuring uniformity across large production runs.

What does a mold maker do?

Injection molding manufacturers specialize in the design, production, and supply of plastic parts and components using the injection molding process. Their responsibilities encompass various stages of manufacturing, from product development to final production. Here’s an overview of what they do:

- Product Design and Development

- Mold Design and Fabrication

- การเลือกใช้วัสดุ

- Production and Molding

- Quality Control and Testing

- Post-Processing and Finishing

GHXLD Custom Plastic Injection Molding Services

GHXLD is a leading injection molding manufacturer that provides innovative solutions for all your injection molding requirements. Whether it’s mold design and fabrication, material selection, injection molding, quality control, or post-processing, GHXLD has you covered.

Contact us today to learn more about our injection molding services and how we can help you achieve your production goals.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Yo, TBJILI is my go-to spot! Always got the newest games and the bonuses are legit. Been cashing out pretty regularly, no cap. Check it out tbjili, you might get lucky too!

Just signed up with 99okwin, and so far, so good! The interface is clean, and I’m already eyeing a few games. Hoping for some big wins! Definitely checking out 99okwin.

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.info/sk/register?ref=WKAGBF7Y

Thinking about putting some cheddar on pixbet365. What’s the general consensus? Solid bookie or nah?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/tr/register?ref=MST5ZREF