在制造方面, 外观的美观度是世间不容忽视的. ABS (丙烯腈·丁二烯·苯乙烯) plastic parts — you will see those in a lot of applications.

They are robust and may be fashioned into many different things. 然而, to get ABS parts to really pop they also have to be bright and shiny.

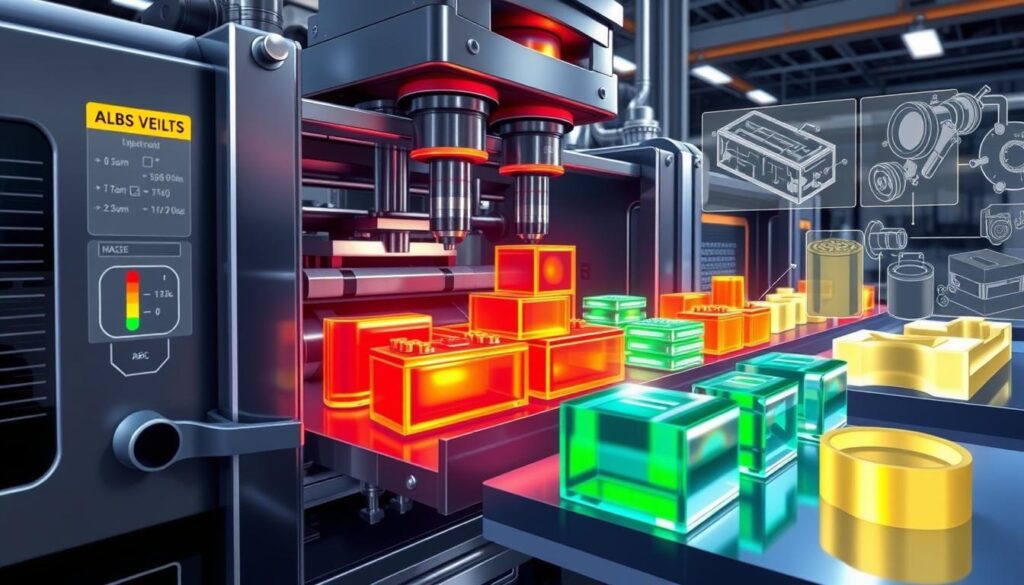

ABS is Best Served with the Injection Molding Process, essential for ABS parts looking their absolute best. To manipulate the ABS material into smooth shiny parts, makers tweak Temperature [压力], Flow of ABS. This gives the parts a better appearance and more worth.

Bright surface is just one of matters when surface Appearance not all is going about looks. It also makes some ABS parts work better or worse. 例如, mirrors can help reflect more light. That’s awesome for applications like car headlights or the screens in electronics.

Have you known the ABS fundamentals on materials properties?

If you want to know in detail the absolute brightening properties of ABS polymer, you should first get to the roots of what ABS really is. ABS (丙烯腈·丁二烯·苯乙烯), is a copolymer with brilliant light reflection qualities. Many consider this to be a popular material also due to the nature of its applications being highly visual

Absorbance and Light Reflection Properties from Chemical Composition

Abs polymer has acrylonitrile, butadiene and styrene in its chemical structure uniquely. This is what ABS is going to be hard, heat resistant and able withstand some impacts The styrene element also gives ABS high surface charateristics, which will result in nice rigid and smooth finish that reflects light.

ABS Natural Surface Features

ABS is famous for the same smooth and even surface. Natural surface quality is unique where it can be naturally reflection of light, making the object visually white and shiny. The surface finish of the injection molding material is appropriate application where brightness and visual appeal are required.

Material Grade on Brightness Impact

Not every ABS material provides the same level of brightness, as a whole. The material grade can really make a big difference in what the molded part winds up looking like. Better Light Reflectivity The best grades of ABS, along an exact additive pack can deliver better light reflection. Which means a richer look with more color and eyes. Selecting a proper ABS material grade is key to obtain the required brightness of final product.

注塑成型,ABS Parts: Process Parameters for Optimal Brightness

To get the right brightness in ABS plastic 部分, injection molding experts must tweak several key settings. 这些包括 模具温度, 注射压力, 和 cooling rate.

这 模具温度 is key for the ABS part’s finish. Warmer molds help the material flow better, making the surface smoother and brighter. 但, too high and it can get damaged or change color. Finding the perfect temperature is crucial for the best brightness.

Injection pressure also affects the ABS part’s surface. More pressure fills the mold better, making the surface even and shiny. Less pressure can leave air pockets and imperfections, making the part look dull.

这 cooling rate of the ABS part is also important. A slow cool helps the material solidify evenly, avoiding defects that can dull the part. Adjusting the cooling system is key for parts that shine brightly and consistently.

| Injection Molding Parameter | Impact on ABS Part Brightness |

|---|---|

| 模具温度 | Higher temperatures promote smoother, more reflective surfaces, but excessive heat can lead to discoloration. |

| 注射压力 | Higher pressures improve mold filling and surface uniformity, enhancing brightness. |

| Cooling Rate | Slower, controlled cooling minimizes defects and maintains a consistent, high-brightness finish. |

By carefully adjusting these key settings, makers can always get ABS parts that shine brightly and meet their needs.

Surface Finishing Techniques for Enhanced Luminosity

Surface finishing techniques are key to making ABS parts shine. 抛光, texture manipulation, and advanced 后处理 are some strategies used. These methods help boost the brightness of injection-molded parts.

Polishing Methods and Their Effects

Polishing is a basic technique that greatly improves ABS parts’ reflectivity. It smooths out the surface, making it mirror-like. This increases light reflection, enhancing the part’s brightness and look.

Different polishing methods, like mechanical buffing or chemical polishing, can change the surface’s brightness and appearance.

Texture Manipulation for Light Control

Texture manipulation is another way to control light on ABS surfaces. Texture manipulation 技巧, like micro-texturing and nano-texturing, create patterns. These patterns can either reflect or diffuse light, giving precise control over brightness.

Post-Processing Technologies

New 后处理 technologies have also improved ABS part luminosity. Post-processing methods, such as plasma treatment or chemical vapor deposition, refine the surface. They enhance light control 和 surface polishing effects.

By choosing and using these techniques, manufacturers can make ABS parts shine. They deliver parts that are not only bright but also visually appealing.

Common Challenges in Achieving Consistent Surface Brightness

Creating bright and flawless ABS parts is a big challenge for those in plastic injection molding. Issues like pitting, streaking, or uneven color can ruin the look of the final product. Problems with melt flow, 温度, or mold design can also lead to poor surface quality.

To solve these problems, it’s key to have good 质量控制 and know how to troubleshoot. Regular checks, monitoring, and analyzing data can help find the causes of defects. 这边走, makers can make the needed changes to fix the issues.

| Common Surface Defects | Potential Causes | Troubleshooting Strategies |

|---|---|---|

| Pitting | Moisture in the material, improper melt temperature, or mold design issues | Ensure proper material drying, optimize melt temperature, and evaluate mold design |

| Streaking | Uneven melt flow, contamination, or poor mold polishing | Adjust injection parameters, implement effective cleaning procedures, and improve mold surface finish |

| Uneven Coloration | Inconsistent material distribution, temperature variations, or improper pigment dispersion | Optimize material feeding, ensure uniform 模具温度, and enhance pigment mixing |

By tackling these common issues with 质量控制, process improvement, and smart troubleshooting, makers can make ABS parts that look great and are consistently bright.

“For consistent surface brightness in injection-molded ABS parts there is really nothing like a complete material understanding, molding process knowledge and best in class quality control methods, achieving it.”

联系我们

是的